Outokumpu Corporation

Investor news/Press release

October 29, 2025 at 08.55 am EET

Outokumpu invests approximately USD 45 million in a chromium metal and enriched ferrochrome pilot plant in the U.S.

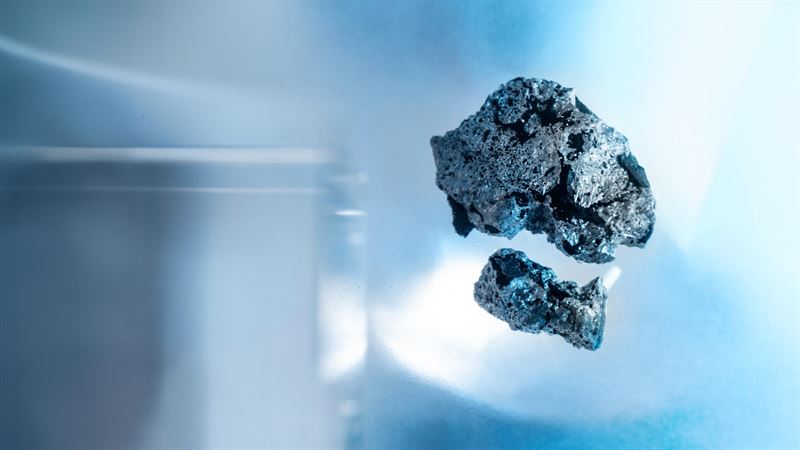

Ferrochrome produced in Outokumpu's R&D lab.

Outokumpu is proceeding with the EVOLVE strategy to enhance the production of critical carbon-free materials, such as chromium metal and enriched ferrochrome. The company invests approximately USD 45 million in a new pilot plant in New Hampshire, U.S., planned to be operational in H1 of 2027. The pilot plant with its unique engineering will represent a significant step forward in Outokumpu's strategy to scale up the proprietary technology announced at the Capital Markets Day in June 2025.

In 2024, Outokumpu established a state-of-the-art laboratory near Boston, U.S. Over the past four years, the technology has been developed and tested, and the company has already successfully scaled production of key materials, such as enriched ferrochrome and chromium metal, from lab-scale (1 g) to pre-pilot-scale (1 kg). Therefore, the aim of the pilot phase is to demonstrate the scalability and industrial feasibility of the process by scaling up from 1 kg to 1 ton of daily production. The two materials that will be produced in the pilot plant are enriched ferrochrome, containing 65% chrome and chromium metal, with more than 90% chrome content. Such an implementation of technology would advance our Ferrochrome business towards specialty metals business.

Following the successful completion of the pilot phase, Outokumpu plans to construct the first industrial-scale plant, with an anticipated annual production capacity of approximately 10,000 tons. The target timeline for the industrial plant to be operational is 2029-2030, and Outokumpu expects to unlock the full commercial potential of the innovative proprietary technology from 2030 onwards.

With this technology, enriched ferrochrome is produced with lower carbon footprint and can be utilized in melt shops and sold externally at higher prices compared to the current offering. The process also enables new production pathways for high-purity metals, such as chromium metal, which is applicable for high-value markets, such as aerospace, defense and energy sectors. Chromium metal is a very hard material with an exceptionally strong heat resistance, making it suitable for demanding industries and applications such as fighter jet engines.

"We are proud to go ahead, in line with our EVOLVE strategy, to produce low-CO2 metals and move up the chromium value ladder. Backed by years of research, we are leveraging proprietary technology targeting premium-priced, high-purity metals essential for demanding sectors. With limited Western supply and growing demand, we see a significant market opportunity for sustainable, high-performance materials", says Stefan Erdmann, Chief Technology Officer (CTO) of Outokumpu.

For more information

Investors: Ulla Paajanen, SVP - Investor Relations and Strategic Advisory, tel. +358 40 763 8767

Media: Päivi Allenius, SVP -Communications and Brand, tel. +358 40 753 7374, or Outokumpu media desk +358 40 351 9840, e-mail media(at)outokumpu.com

Outokumpu is accelerating the green transition as the global leader in sustainable stainless steel. Our business is based on the circular economy: our products are made from 95% recycled materials, which we then turn into fully recyclable stainless steel. This steel is utilized in various applications across society, including infrastructure, mobility, and household appliances. We are committed to 1.5°C target to mitigate climate change, and with up to 75% lower carbon footprint than the industry average, we support our customers to reduce their emissions. Together, we are working towards a world that lasts forever. Outokumpu Corporation employs approximately 8,700 professionals in close to 30 countries, with headquarters in Helsinki, Finland and shares listed in Nasdaq Helsinki. Read more: www.outokumpu.com