Purpose-built platform reduces time, cost, and complexity in developing next-generation PCB Stator motor systems.

NEEDHAM, MASSACHUSETTS / ACCESS Newswire / November 12, 2025 / ECM PCB Stator Tech has unveiled a suite of more than six internally developed motor drives and controllers engineered specifically for PCB Stator applications, a major step in closing the loop between digital motor design and intelligent hardware control.

The new platform includes a growing set of hardware reference designs optimized for ECM's patented PCB Stator motors, enabling scalable, cost-effective, and high-performance control across a wide range of use cases, from compact servos and precision haptics to multi-kilowatt HVAC and robotics systems.

From Digital Model to Functional Motor - Faster Than Ever

By combining tightly integrated hardware, flexible firmware, and a software layer purpose-built for real-time control, ECM's new platform dramatically simplifies the path from simulation to fully functional motor systems. This innovation supports faster prototyping, easier system integration, and lower total cost of ownership, making the adoption of ECM's disruptive motor technology more accessible than ever.

This launch marks the next milestone in ECM's ECMpowered ecosystem - where software-defined motors, intelligent control systems, and compact, efficient form factors converge to redefine electric motion design.

"Our goal is to close the loop between motor design, firmware, and control," said Dr. Eric Ponce, Director of Research and Development at ECM PCB Stator Tech. "With this platform, our partners can move from digital motor models to intelligent, production-ready control systems in record time and with minimal friction."

For a closer look at the engineering behind ECM's new controller platform, watch Dr. Eric Ponce's recent PrintStator in Motion talk here.

Highlights of ECM's New Drive and Controller Platform

Hardware: Rapid Prototyping Meets Scalable Performance

More than Six flexible hardware reference designs

Scalable from sub 100 W to multi-kW applications

Reduction of controller and system-level BOM cost

Built-in protection (overcurrent, overvoltage, thermal)

Interfaces for sensored and sensorless feedback

Tightly integrated custom designs leveraging ECM's unique form factor

Firmware: Precision Meets Adaptability

Imports data directly from PrintStator Motor CAD

Real-time parameter estimation and adaptive fault detection

Supports sensorless and sensored feedback flexibility

High-speed FOC control loops (>20 kHz) for smooth, high-precision motion

Common firmware platform across power levels and controller topologies

Software Layer: Real-Time Insights and Control

Enables real-time tuning, measurement, and data logging

Supports seamless integration into custom applications or third-party systems

Enabling a Full-Stack Motor Ecosystem

This new platform builds on ECM's mission to provide a full-stack solution for electric motor innovation - from software-defined motor design with PrintStator, to high-efficiency axial flux motors, and now, to intelligent motor control systems. By aligning motor geometry, materials, control algorithms, and interface design, ECM empowers engineers and OEMs to rethink what's possible in motion systems - and to do it faster.

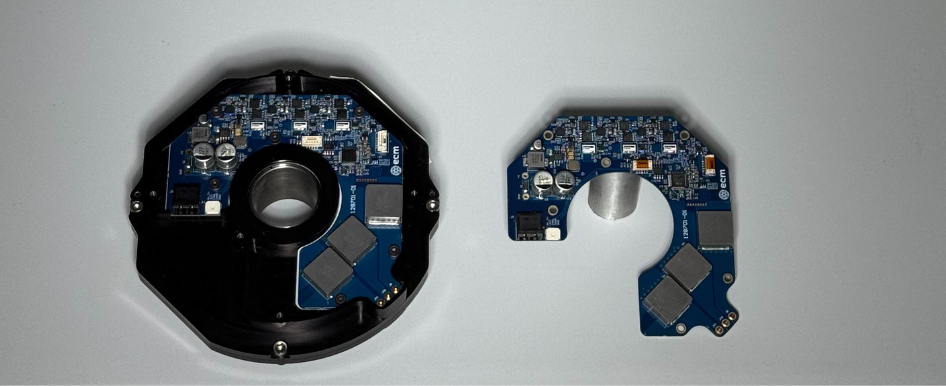

ECM PCB Stator Evaluation Motors feature tightly integrated control solutions

To be ECMpowered means that motors are not simply built, but engineered from the ground up through software intelligence and PCB Stator design to deliver unmatched performance, speed-to-market, and total system value.

The ECMpowered badge is a mark of advanced electric motor innovation, signalling that partners and products are driving the future of electrification with next-generation performance, efficiency, and design.

About ECM PCB Stator Tech

ECM PCB Stator Tech delivers the only full-stack platform for electric motor innovation. It empowers partners to design, prototype, and optimize next-generation PCB Stator motors with precision and speed.

With PrintStator Motor CAD and patented axial flux hardware, ECM enables the development of compact, efficient, and quiet motors that:

Use up to 80% less raw material

Weigh up to 70% less than traditional motors

Achieve efficiencies in excess of 90 percent

Eliminate cogging with near-zero EMI and acoustic signature

Enable vertical integration and supply chain control

Learn more at www.pcbstator.com or watch: "How Does a PCB Stator Work?" and "A New Way to Build Motors Without Winding Lines"

Contact Information

Sam Jones

Director of Marketing and Communications

sjones@pcbstator.com

www.pcbstator.com

SOURCE: ECM PCB Stator Tech

View the original press release on ACCESS Newswire:

https://www.accessnewswire.com/newsroom/en/industrial-and-manufacturing/ecm-introduces-new-motor-drive-and-controller-platform-to-accelerate-a-1100089