ASNT Annual Conference - Orlando

Already trusted by global OEMs, the Vienna-based scale-up ramps up operations in the U.S. - eliminating coupling fluids, reducing inspection costs, and automating defect detection with its proprietary testing system.

VIENNA, AT / ACCESS Newswire / September 2, 2025 / XARION Laser Acoustics, the Vienna-based pioneer in contact-free ultrasonic inspection, is presenting its latest solutions at the ASNT Annual Conference in Orlando. Known for its patented Laser-Excited Acoustics (LEA), XARION offers a dry, fully automatable solution that eliminates the need for coupling media like gels or water. Already trusted by industry leaders such as Northrop Grumman, the technology is redefining non-destructive testing in advanced manufacturing. Visitors to ASNT can meet the team on-site and experience live demos of the system (Orlando, Florida; October 6-9, 2025 | Booth 125).

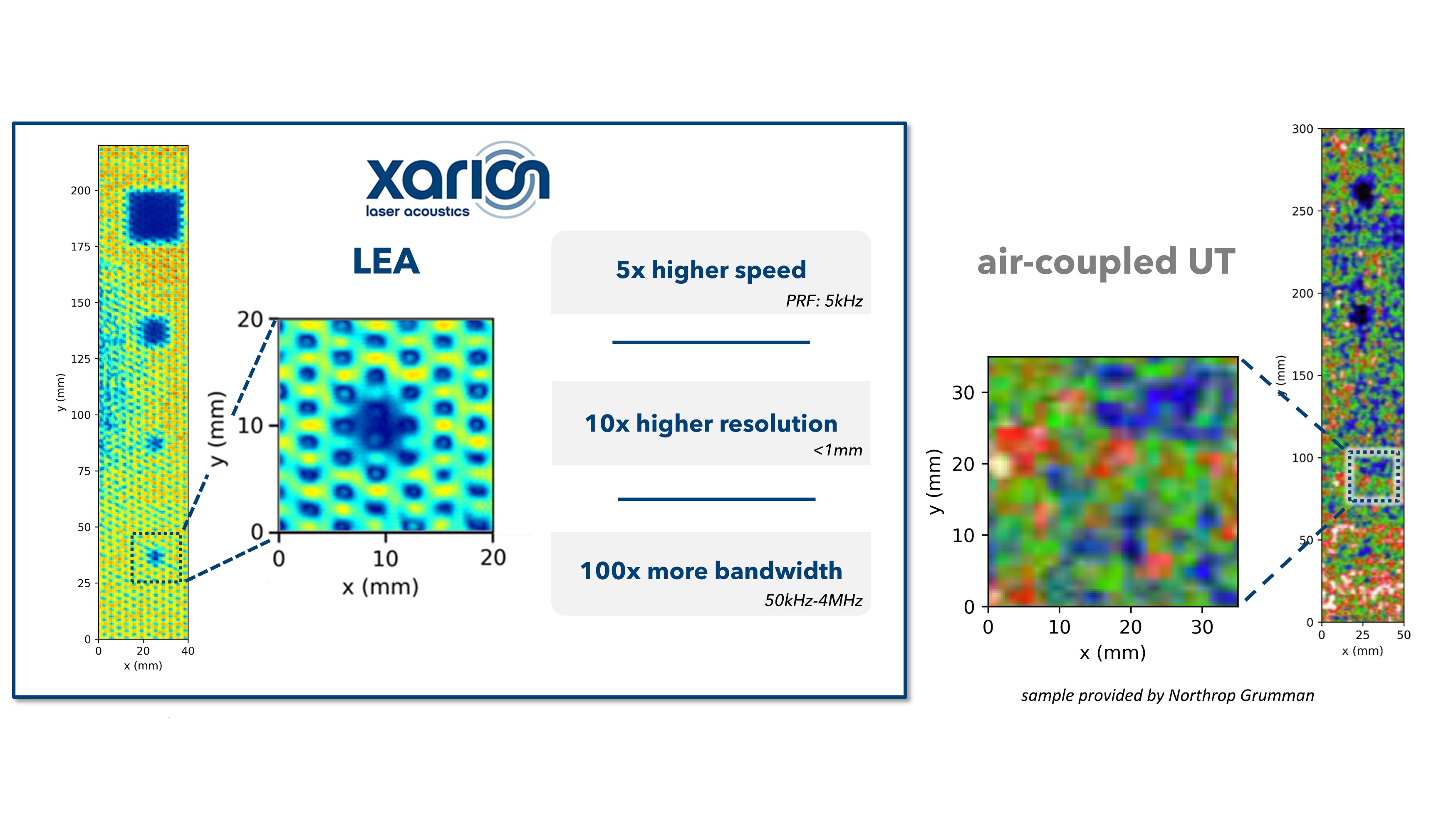

Inspection of a CFRP sandwich panel with a honeycomb core by LEA and traditional air-coupled UT. Frequency filtering of LEA's broad bandwidth enables the detection of single cell defects.

Overcoming the limits of conventional ultrasonic testing

In the aerospace industry, where even single defects can lead to catastrophic events, quality control (QC) is of utmost importance. Nevertheless, the established non-destructive testing (NDT) methods have remained similar for decades. Traditional setups still rely on bulky water immersion tanks or splashing waterjet systems. These approaches complicate workflows and limit the materials that can be tested effectively. XARION's LEA system removes these constraints by delivering fast, high-resolution testing without contact media.

Contactless precision for advanced materials

Using a pulsed laser, XARION's LEA system excites ultrasonic waves directly within the tested material. The company's proprietary optical microphone, a matchbox-sized sensor, detects those ultrasonic waves without physical contact. "Our solution offers enough flexibility to inspect a wide range of material combinations - from carbon fiber reinforced polymers (CFRP) and adhesives to metals like steel and aluminum to ceramics," states Dr. Balthasar Fischer, founder of XARION Laser Acoustics. This flexibility makes LEA suitable not just for the aerospace industry but also for a broad range of sectors where the highest-level QC counts.

High resolution meets high throughput

Our LEA technology provides precision unlike anything seen before in air-coupled ultrasonic testing. Even single-cell flaws in honeycomb-core CFRP structures are visible (Fig. 1). The small sensor head can be either used in single-sided or through transmission mode, characterizing even long, hollow, curved shapes, such as a helicopter tail boom. In single-sided measurements, XARION's novel Pulse-Echo sensor head (Fig.3) goes even further than comparative methods, giving information not only on defect size and position, but also its depth. With a wide frequency bandwidth (50 kHz to 4 MHz) and robust signal processing, the system produces high-resolution images at scan speeds up to 1 meter per second, which is important for manufacturing lines.

From R&D to automized inline inspection

To ease adoption, XARION offers LEAsys, a turnkey inspection system for R&D environments (Fig. 3). This allows manufacturers to explore the capabilities of LEA before scaling up to full in-line integration. "Customers appreciate the ability to validate performance in-house before committing to system-wide changes," explains Dr. Josef Pörnbacher, Head of Application Development. In production lines, for example for the control of weld spots in automotive components, the LEA sensor is mounted on a robotic arm and offers seamless automatization (Fig. 2). In industries where failure is no option, quality control must evolve beyond its traditional limitations. XARION's LEA technology provides an essential tool to ensure quality and safety for U.S. customers.

--

Founded in 2012, XARION Laser Acoustics GmbH develops and manufactures innovative, laser-based acoustic sensors. Its patented optical microphone enables contactless ultrasonic inspection across a wide frequency range-ideal for high-resolution material testing and in-line process monitoring. XARION's solutions serve industries where precision, reliability, and speed are critical, including aerospace, automotive, microelectronics, and battery manufacturing. With over 30 international patents and leading industrial partners, XARION is setting new standards in ultrasonic quality assurance.

Contact Information:

XARION Laser Acoustics GmbH

Ghegastrasse 3

A - 1030 Wien / Austria

Eva Porodko - Senior Project Manager

E-Mail: welcome@xarion.com

Phone: +43 1 907 60 76 23

Fax: +43 1 9076076 99

https://xarion.com/

Contact Information

Wilhelm Fuchs

Public Relations

kontakt@jetzt-pr.de

+49211748595161

SOURCE: XARION Laser Acoustics GmbH

Related Images

The novel Pulse-Echo sensor head from XARION provides information on defect size, shape, and depth, which can be crucial for quality control. With its compact, matchbox-sized design, the sensor also enables measurements on complex geometries.

The LEAsys (left) is a user-friendly, turnkey solution designed for use in R&D departments. For automated quality control the LEA sensor is mounted on a robotic arm (right).

View the original press release on ACCESS Newswire:

https://www.accessnewswire.com/newsroom/en/industrial-and-manufacturing/xarion-expands-u.s.-presence-aerospace-grade-contact-free-ultrasonic-q-1067399