SINGAPORE, Oct. 21, 2025 (GLOBE NEWSWIRE) -- Verde AgriTech Ltd. (TSX: NPK | OTCQX: VNPKF) ("Verde" or the "Company"), is pleased to report ionic-adsorption behaviour confirmed across multiple trenches at the Minas Americas Global Alliance Project ("Minas Americas" or the "Project") in Minas Gerais, Brazil. Ammonium-sulfate leach tests returned primary leach solutions ("PLS") with very strong magnet rare earth (neodymium (Nd), praseodymium (Pr), dysprosium (Dy), terbium (Tb)) grades and exceptionally low impurities (thorium/ uranium (Th/U) at, or below, detection).

Highlights

- Best leachates (0.5M (NH4)2SO4, 30 min): up to 667 mg/kg of DREO (total desorbable rare earth oxide) ("DREO") and up to 278 mg/kg of magnetic rare earth oxide ("MREO") (Nd+Pr+Dy+Tb), showing ionic adsorption behaviour and demonstrating strong magnet-REE proportion in these initial tests.

- NdPr in leachate up to 268 mg/kg (PT-36), with Dy+Tb up to 9 mg/kg; multiple trenches exceed 150 mg/kg MREO in PLS.

- Head grades are high and laterally continuous: top MREO samples range 1,306-2,182 ppm, within 6,081-8,930 ppm TREO.

- Ultra-low contaminants in PLS: Th and U not detected in the best intervals; Fe and Al minimal, supporting selective ion-exchange.

Top Leachate Intervals and Matching Head Grades

Table 1 - Top Disordable Intervals

| Project/Source | Basis | Head TREO (ppm) | Head MREO (ppm) | DREO in PLS (mg/kg) | MREO in PLS (mg/kg) | Nd2O3 (mg/kg) | Pr6O11 (mg/kg) | Dy2O3 (mg/kg) | Tb4O7 (mg/kg) | Key impurity notes |

| PT-36 | Trench (0-1 m) | 7,181 | 1,593 | 667 | 278 | 209 | 59 | 7 | 2 | Th & U ND; Fe ND |

| PT-34 | Trench (1-2 m) | 8,615 | 2,182 | 578 | 240 | 187 | 45 | 7 | 2 | Th & U ND; Fe ND |

| PT-42 | Trench (0-1 m) | 4,605 | 1,096 | 383 | 167 | 129 | 33 | 4 | 1 | Th ND (~3 mg/kg Th max); Fe ND |

Notes: DREO and element grades above are measured directly in the primary leach solution (PLS) from ion-exchange tests; Head grades are from the same trench intervals. ND = not detected.

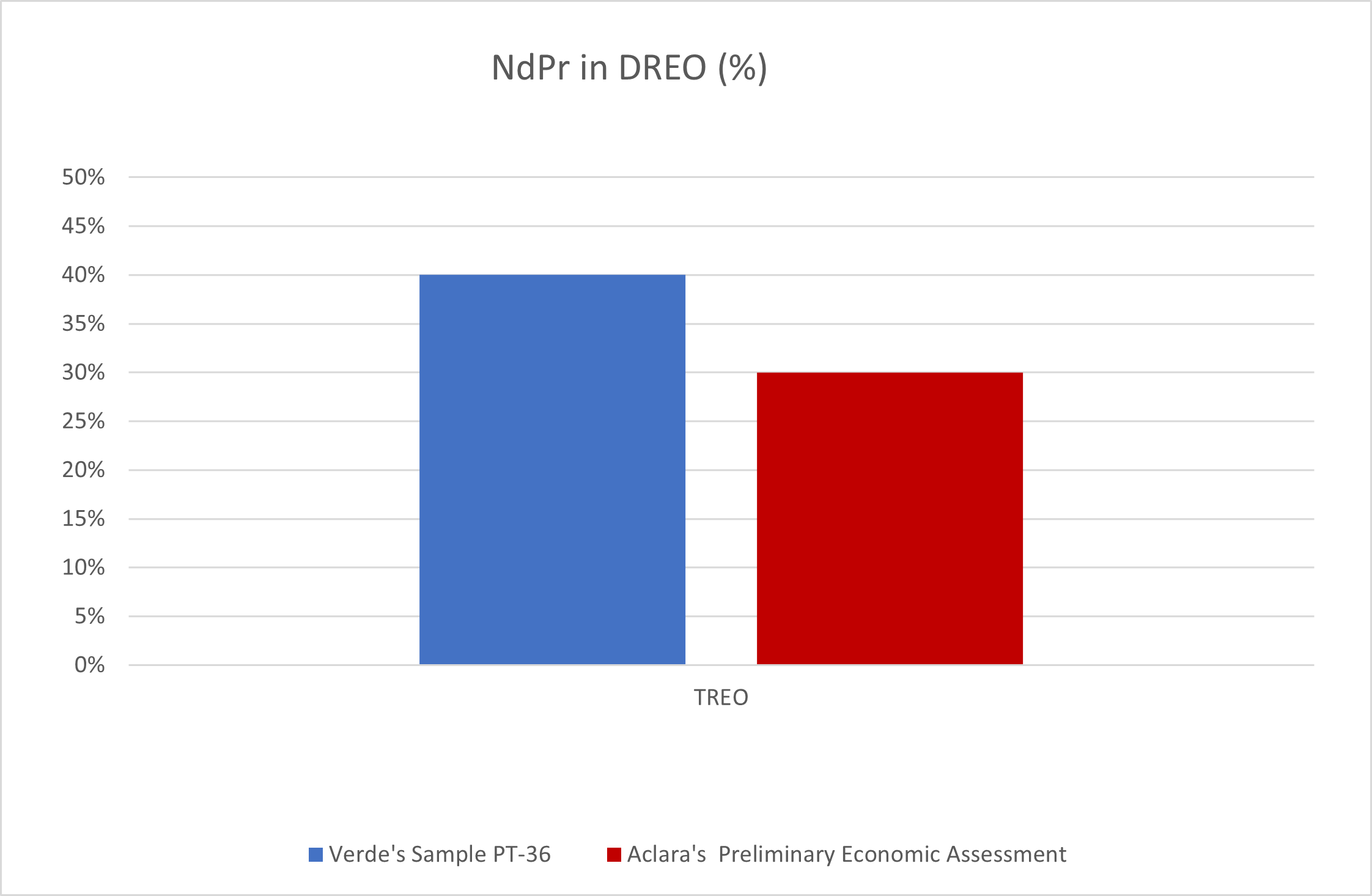

Magnet REEs dominate the leachate (>40% of dissolved REO). The magnet rare-earth oxides (MREO = Nd2O3 + Pr6O11 + Dy2O3 + Tb4O7) constituted over 40% of the dissolved REO in Verde's best PLS samples-an exceptional selectivity for the value-driver elements. Quantitatively, PT-36 returned DREO of ~667?mg/kg with MREO of ~278?mg/kg (˜41.7% MREO; NdPr ~268?mg/kg; Dy+Tb ~9?mg/kg). PT-34 (1-2?m) showed DREO of ~578?mg/kg and MREO of ~240?mg/kg (˜41.5%), while PT-42 (0-1?m) reported DREO of ~383?mg/kg and MREO of ~167?mg/kg (˜43.6%). This >40% MREO share-paired with very low Th/U and minimal Fe/Al (iron/aluminium) in solution-indicates high-value, magnet-grade enrichment in the leachate and provides a strong technical basis for efficient downstream upgrading to tight-spec mixed rare earth carbonate (MREC).

Cerium is selectively suppressed in solution. Under the diagnostic 0.5?M ammonium-sulfate, 30-minute leach screen, cerium consistently reports at very low concentrations in the primary leach solution (PLS) relative to the head composition-an ionic-clay hallmark that materially simplifies downstream purification. in Verde's top intervals, CeO2 in PLS ranges ~16-91?mg/kg, while the dissolved-REE (DREO) totals 383-667?mg/kg; that means cerium represents only ~4-14% of dissolved REO in these best samples. For example, at PT-36 (0-1?m) the head assay carries ~3,563?ppm CeO2 within 7,181?ppm TREO, yet the PLS contains ~91?mg/kg CeO2 against ~667?mg/kg DREO (˜14% Ce in solution). At PT-34 (0-1?m) and PT-34 (1-2?m), CeO2 in PLS is ~16-28?mg/kg versus ~383-578?mg/kg DREO (˜4-5% Ce in solution), further confirming preferential desorption of magnet REEs over cerium under mild conditions. Th and U are at or below detection; iron (Fe) is not detected in the best PLS, reinforcing a clean leach signature.

Ionic-Clay Rare Earths - Rarer Geology, Higher Strategic Appeal, and Why "Clean" Clays are King

Ionic-adsorption clays (IACs) are geologically rarer than hard-rock rare-earth systems. They form only where REE-bearing source rocks have been deeply weathered for long periods in warm, humid climates, where the right clay minerals can weakly adsorb REEs and where stable landscapes preserve these horizons close to surface. Those conditions occur in limited belts globally, which is why confirmed IAC districts command outsized strategic interest. Moreover, they are shallow, soft, and tightly aligned to the magnet-grade demand story powering EVs, robots, and wind.

From a developer's risk lens, well-behaved ionic clays can mitigate key execution risks. Their near-surface, free-digging nature reduces mining complexity; ambient-condition desorption allows compact, modular buildouts; and faster test-iterate cycles are possible if early metallurgy confirms ionic behavior and a "clean" liquor. Cleanliness is king in ionic clays. IAC domains that co-dissolve fewer contaminants (e.g., Fe/Al/Mn/alkalies) typically need fewer purification stages, consume less reagent, simplify residue handling, and enable a tighter-spec mixed rare earth carbonate (MREC) that downstream processors prize. The upshot: lower impurity loads can translate into simpler, smaller circuits and materially lower capital intensity than high-impurity clay variants-accelerating credible pathways to marketable concentrate. The project ultra-low contaminants in PLS are illustrated in Table 2.

Table 2 - Weight Percent (Wt%) of Key Impurities in PLS for Top Disordable Intervals

| Project/Source | Basis | Al (Wt%) | Ca (Wt%) | Fe (Wt%) | Ni (Wt%) | Th (Wt%) | U (Wt%) |

| PT-36 | Trench (0-1 m) | 0,00391 | 0,01508 | <0,0002 | 0,000266 | 0,000259 | <0,000004 |

| PT-34 | Trench (1-2 m) | 0,00158 | 0,06842 | <0,0002 | 0,00054 | <0,00002 | <0,000004 |

| PT-42 | Trench (0-1 m) | 0,00338 | 0,00968 | <0,0002 | 0,000781 | 0,000292 | <0,000004 |

Light, Heavy or Magnet?

Rare earth elements are often labeled "light" (La-Gd) and "heavy" (Tb-Lu, plus yttrium), but the market does not split that neatly and definitions vary among authorities. Deposits coproduce a basket of elements, so outputs are governed by geology and processing rather than preference. Many heavy rare earths feed small, highly specialized uses-laser media, medical imaging crystals, specialty optics-where ultra-tight purity and performance specs drive qualification and price. High unit prices, in other words, reflect specification intensity and tiny volumes, not large underlying markets.

What sets market scale and strategic relevance are the magnetic rare earths. NdPr form the backbone of high-performance Nd-Fe-B magnets, while small additions of dysprosium or terbium (Dy/Tb) enable high-temperature resilience. These magnets are critical in EV drivetrains, robots, wind turbines, and advanced industrial systems, with few practical substitutes at comparable torque density and efficiency-and supply chains remain geographically concentrated. As a result, magnetic REEs-especially NdPr, with Dy/Tb where needed-are the primary demand drivers and the most strategic focus across the value chain.

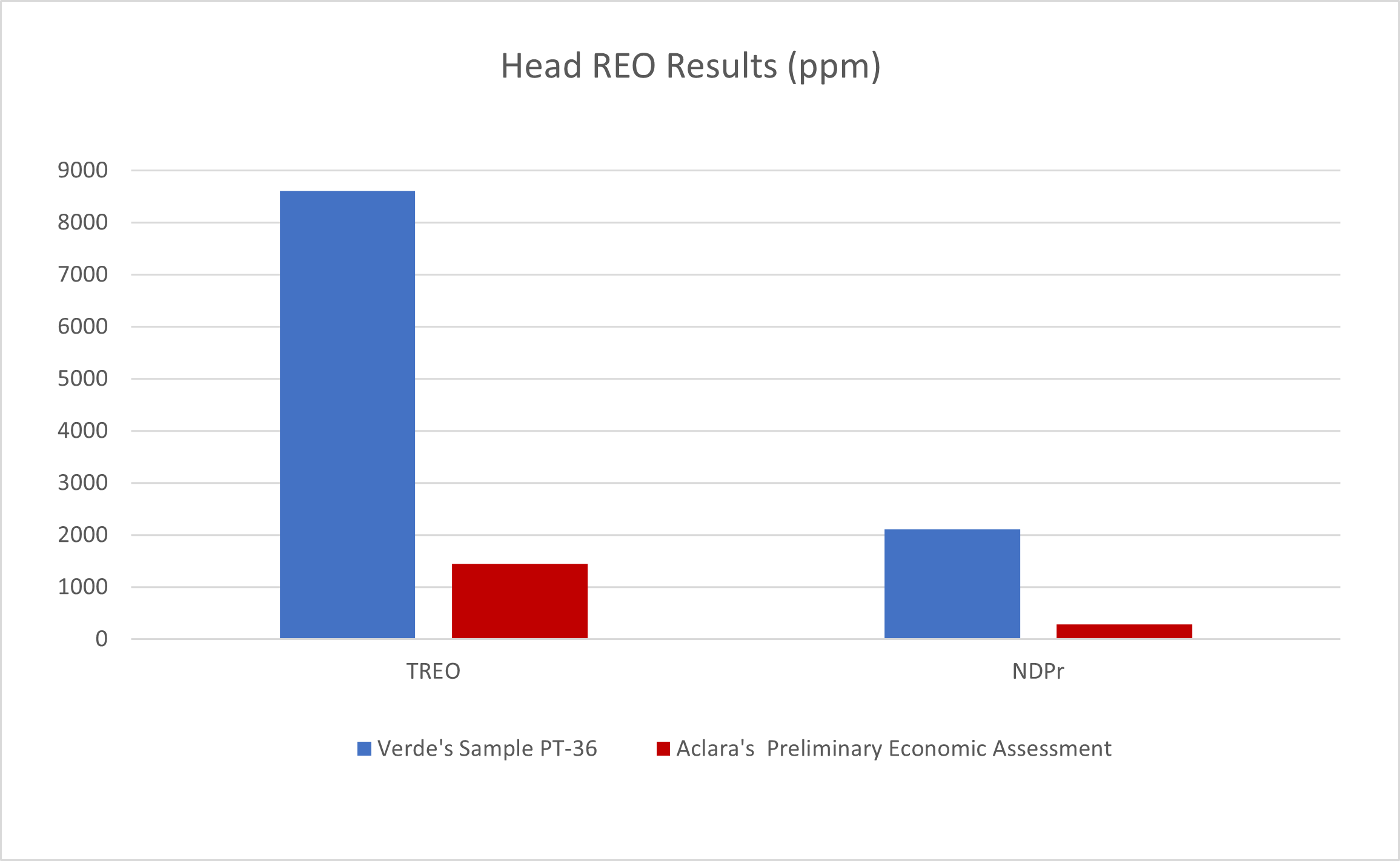

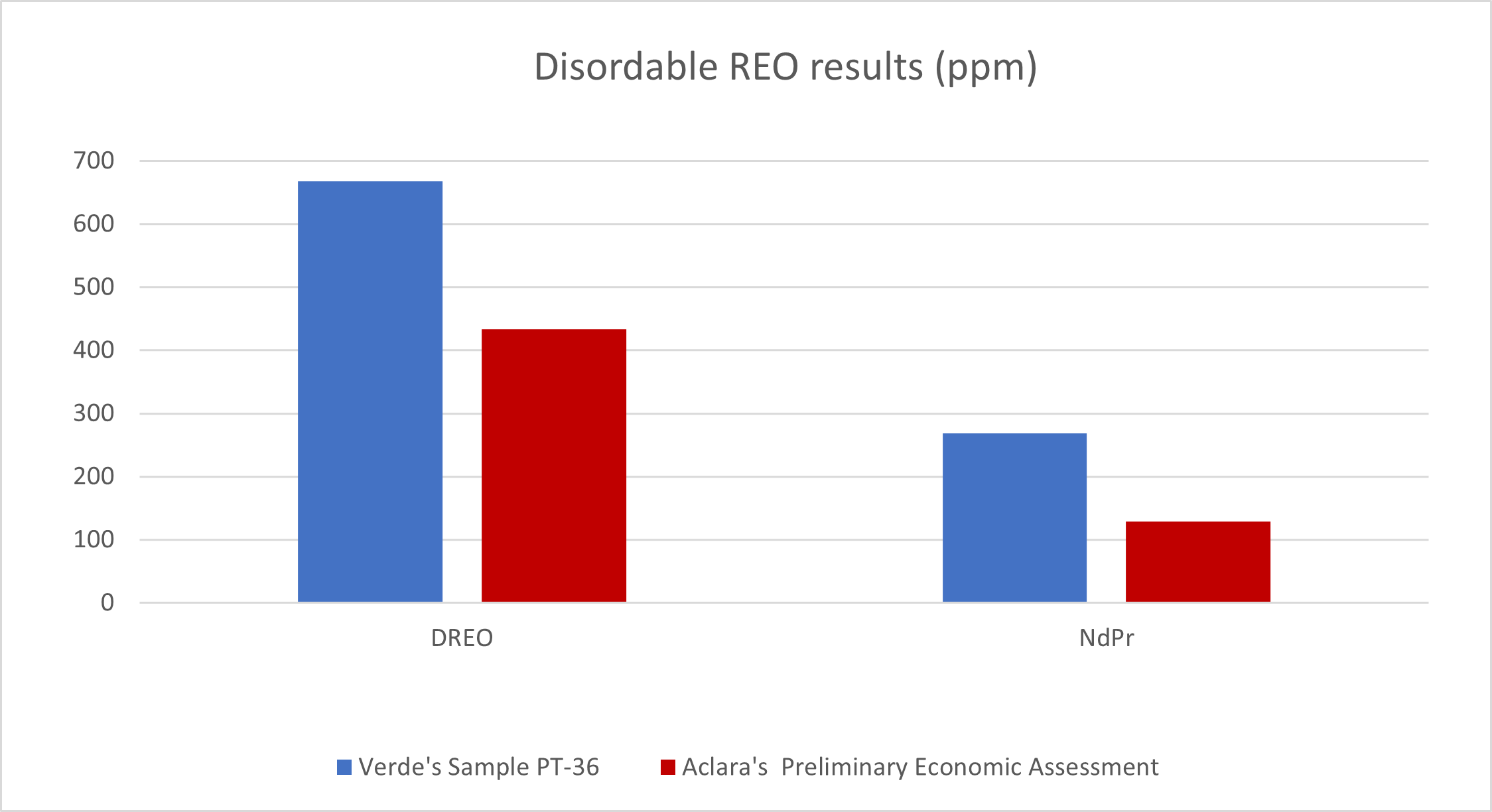

How Minas Americas Compares (Head Grade and Leachate) to Aclara's Carina Project (Brazil)

Head grade (oxide ppm): Aclara's Carina Indicated Resource (Grand Total) reports Nd2O3 ~221 ppm, Pr6O11 ~63 ppm, Dy2O3 ~38.9 ppm and Tb4O7 ~6.4 ppm (~329 ppm MREO) within 1,1452 ppm TREO. The Project selected trench intervals show materially higher head grades (e.g., PT-34: 2,182 ppm MREO within 8,615 ppm TREO).

Leachate (PLS) concentrations: Aclara disclosed average high-grade RC intervals of ~434 mg/kg DREO with ~129 mg/kg NdPr and ~22 mg/kg Dy+Tb (~152 mg/kg MREO). The Project's best intervals yield up to 667 mg/kg DREO and up to 278 mg/kg MREO (NdPr to 268 mg/kg), exceeding those averages on a strictly apples-to-apples basis. This like-for-like comparison is summarized in Table 3 and illustrated in Figures 1-3.

Table 3 - Verde - Minas Americas vs.Aclara - Carina

| Project/Source | Basis | TREO (ppm) | MREO (ppm) | DREO in PLS (mg/kg) | MREO in PLS (mg/kg) | NdPr in PLS (mg/kg) |

| PT-36 | Trench (0-1 m) | 7,181 | 1,593 | 667 | 278 | 268 |

| PT-34 | Trench (1-2 m) | 8,615 | 2,182 | 578 | 240 | 232 |

| PT-42 | Trench (0-1 m) | 4,605 | 1,096 | 383 | 167 | 162 |

| Aclara - Carina | Indicated (avg) / PEA | 1,452 | ~329 | ~434 | ~152 | ~129 |

Figure 1 - Minas Americas vs. Carina - Head REO Results

Figure 2 - Minas Americas vs. Carina - Disordable Results

Figure 3 - Minas Americas vs. Carina - NdPr in DREO Results

Aclara's head grades above are averaged over a large Indicated Resource; the Project results are early-stage trench intervals. Nonetheless, on a leachate concentration basis (what goes into the plant), the Project's best PLS magnet grades are competitive to superior while maintaining exceptionally low impurities.

* Aclara Resources Mineração Ltda.; GE21 Consultoria Mineral. Carina Rare Earth Element Project - Preliminary Economic Assessment Update. GE21 Project No. 240205. May 3, 2024. 322?p.

Metallurgy: Why the First SGS Screen is Conservative and Why Stage Two Testing Lifts Recoveries

All leach results reported today come from an SGS Geosol screening test designed to answer a simple question: Are the rare earths ion adsorbed and therefore readily exchangeable? To keep that diagnostic clean and comparable, the procedure intentionally uses a single, short leach (0.5 M ammonium sulfate, ~30 minutes) on the as received, screened material and then reads the dissolved rare earths in the solution. It does not attempt to maximize extraction. In our program, SGS applied method ICM694 (0.5 M (NH4)2SO4; 30 minute contact) after routine sample prep; results are reported as oxides (REO). This is the right first step for ionic clay projects because it isolates the exchangeable fraction and demonstrates low impurity solubilization. For example, in sample OB56 the leachate contained ~383 mg/kg TREO including ~127 mg/kg Nd2O3 and ~29 mg/kg Pr6O11, with Th and U near detection limits-evidence of selective ion exchange with minimal contaminant carryover under very mild conditions.

Because this diagnostic is purposefully mild, it under reports what a plant level flowsheet can achieve. Several built in limitations suppress extraction: (i) a single short contact rather than multiple counter current stages; (ii) fixed ionic strength (0.5 M) and no pH ramping to keep clays dispersed and prevent readsorption; (iii) no pre conditioning/attrition to expose exchange sites; (iv) no residence time optimization or temperature control; and (v) no recycle/bleed management of the leach liquor. In practice, proper metallurgical testing for ionic clays moves to staged agitated and/or percolation leaching with controlled pH (typically mildly acidic), optimized solid-liquid ratios, higher or stepped salt strengths, dispersants to limit flocculation, and counter current washing. These steps systematically (1) access additional exchange sites, (2) prevent rare earth readsorption as the solution becomes depleted, and (3) concentrate REE in solution while continuing to show low co leaching of Al/Fe/Si. Our initial dataset already points to that selectivity: major gangue oxides are very low in solution, and radioactive/penalty elements are at or near zero-favorable foundations for scaled processing.

What to expect next: Stage two metallurgical work for Verde's Preliminary Economic Assessment, expected to be released in Q2 2026, will therefore implement multi-stage, counter current leaching and washing sequences (agitated and column), pH/ionic strength profiling, residence time optimization, and dispersion control. The objective is to translate today's conservative, single pass screen into materially higher extractions of NdPr, Dy and Tb in line with commercial ionic clay practice-while preserving the clean impurity profile indicated by the SGS screen. As those flowsheet elements are introduced, recoveries typically step up materially from the initial screen because we are no longer constrained by a one and done 30-minute contact at fixed strength. We will report those stage two results as they are completed.

QA/QC and Qualified Person

Sample preparation and analytical methods. Samples were analyzed by SGS Geosol Geosol Laboratórios Ltda. (Vespasiano, Brazil), an ISO/IEC 17025:2017-accredited and independent commercial laboratory. For total element concentrations, samples underwent lithium metaborate fusion with ICP-OES/ICP-MS finish (SGS method codes IMS95A/ICP95A). Selective leachates were prepared using a 0.5 M ammonium sulfate leach for 30 minutes (SGS method ICM694) with ICP-MS finish.

QA/QC. The Company inserted certified reference materials, blanks and field/pulp duplicates at ~12% of the sample stream, and monitored laboratory internal controls. The QA/QC results were reviewed by the Qualified Person and were within acceptable limits for this stage of exploration.

Qualified Person. The scientific and technical information in this news release has been reviewed and approved by José Márcio Matta Machado Paixão, FAusIMM, who is a Qualified Person as defined by NI 43-101 and is independent of the Company within the meaning of NI 43-101. Mr. Paixão has verified the data disclosed herein by reviewing laboratory certificates, QA/QC performance (blanks/CRMs/duplicates) and analytical procedures.

About Verde AgriTech

Verde AgriTech is dedicated to advancing sustainable agriculture through the innovation of specialty multi nutrient potassium fertilizers. Our mission is to increase agricultural productivity, enhance soil health, and significantly contribute to environmental sustainability. Utilizing our unique position in Brazil, we harness proprietary technologies to develop solutions that not only meet the immediate needs of farmers but also address global challenges such as food security and climate change. Our commitment to carbon capture and the production of eco-friendly fertilizers underscores our vision for a future where agriculture contributes positively to the health of our planet. For more information on how we are leading the way towards sustainable agriculture and climate change mitigation in Brazil, visit our website: https://verde.ag/en/home.

Cautionary Language and Forward-Looking Statements

This news release contains "forward-looking information" and "forward-looking statements" (together, "FLI") within the meaning of applicable Canadian securities laws. FLI relates to future events or performance and reflects management's current expectations and assumptions. FLI in this news release includes, but is not limited to, statements regarding: the interpretation and significance of exploration and leach test results; the potential for ionic-adsorption clay mineralization and for economic extraction of rare earth elements; the selectivity of magnet rare earths in solution and implications for processing; comparisons to other projects; anticipated metallurgical programs and flowsheet development (including staged, counter-current leaching and washing); the expected timing, scope and outcomes of further testwork and studies (including a potential preliminary economic assessment (PEA)) currently targeted for release in Q2 2026; plans for project advancement; potential strategic initiatives and partnerships; and the timing and content of future updates.

Material assumptions

Material factors and assumptions used in developing the FLI include, without limitation: that trench and leach results are representative of broader mineralized horizons; continuity of ionic-adsorption behaviour; scalability of laboratory procedures to pilot or commercial settings; availability and performance of reagents and process consumables; the ability to further optimize leaching, washing and impurity control while maintaining selectivity; reasonable access to the Project area, services and infrastructure; the availability of financing on acceptable terms; stable political, regulatory, community and permitting environments; sustained demand and pricing for rare earth products (including Nd, Pr, Dy and Tb); and exchange rates and operating cost inputs consistent with historical ranges.

Material risk factors

FLI is subject to known and unknown risks, uncertainties and other factors that may cause actual results to differ materially. These include, without limitation: risks inherent to early-stage exploration projects; that subsequent work may not confirm initial exploration or leach results; metallurgical risks in scaling from bench to pilot/industrial operations; sampling, analytical and interpretive uncertainties; comparisons to peer projects that may not be valid due to differences in geology, scale, test conditions, project stage or assumptions; commodity price and exchange-rate volatility; access to capital; cost inflation and supply-chain disruptions; availability of water, power, reagents and skilled labour; environmental, permitting, title, tenure and community risks (including Indigenous engagement); changes in laws, regulations, policies or enforcement; political and country risk; counterparty and offtake risks; and the other risks set out in the Company's most recent Annual Information Form, MD&A and other continuous disclosure documents available under the Company's profile at www.sedarplus.ca.

Caution to readers

Although the Company believes the assumptions and expectations reflected in the FLI are reasonable as of the date hereof, no assurance can be given that they will prove correct. Readers are cautioned not to place undue reliance on FLI. The FLI herein is made as of the date of this news release, and the Company does not undertake any obligation to update or revise such FLI except as required by applicable securities laws. The Company's policy is to update previously disclosed material FLI as required by NI 51-102 through subsequently filed MD&A or news releases.

Technical and NI 43-101 Cautionary Statements

The exploration and test results reported are preliminary in nature and do not constitute mineral resources or mineral reserves as defined by National Instrument 43-101 - Standards of Disclosure for Mineral Projects (NI 43-101). There is no certainty that further exploration will result in the delineation of mineral resources or reserves, that any economic analysis will be completed, or that any development decision will be made.

Any discussion of a potential PEA relates to a contemplated future study. No PEA results are being disclosed in this news release. If a PEA is completed and disclosed in the future, the Company will include all cautionary language required by NI 43-101 for any economic analysis that includes or is based on inferred mineral resources.

Reported impurity and radionuclide observations (e.g., thorium/uranium below detection in certain intervals) are limited to the methods, detection limits and sample intervals tested and may not be representative of the property as a whole.

Comparisons to other issuers' properties and results (including Aclara's Carina Project) are provided for context only, are based on public disclosures and/or cited technical sources, and are not necessarily indicative of results that may be achieved at the Company's Project. Differences in geology, testwork, scale, stage of development and assumptions can materially affect outcomes.

The scientific and technical information in this news release has been reviewed and approved by a Qualified Person under NI 43-101 as disclosed herein. Terms such as TREO, MREO and DREO are used as defined in the news release for clarity and are not CIM-defined categories.

For additional information please contact:

Cristiano Veloso, Chief Executive Officer and Founder

Tel: +55 (31) 3245 0205; Email: investor@verde.ag

www.verde.ag | www.investor.verde.ag

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/8fa436a0-c9a0-4e43-b28f-514433cf8839

https://www.globenewswire.com/NewsRoom/AttachmentNg/92cb4e62-e576-461d-b181-d7e2f73f0729

https://www.globenewswire.com/NewsRoom/AttachmentNg/a0672cb1-c216-499a-adb7-4531ab957c38