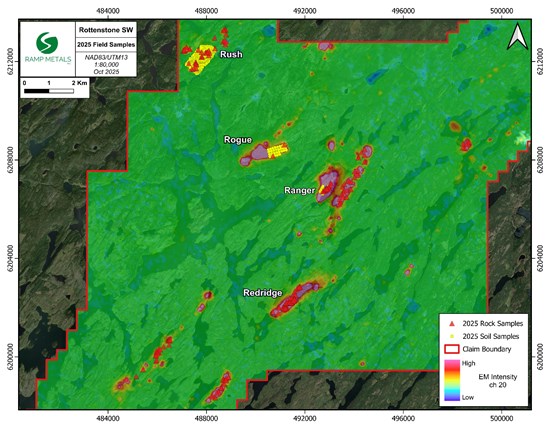

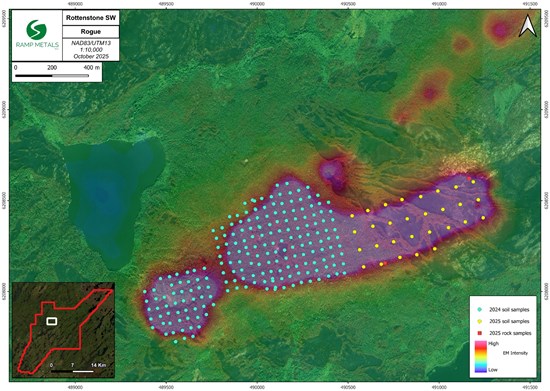

Vancouver, British Columbia--(Newsfile Corp. - October 21, 2025) - Ramp Metals Inc. (TSXV: RAMP) ("Ramp Metals" or the "Company") is pleased to announce the completion of the Company's fall 2025 field program at its Rottenstone SW project in Saskatchewan. A mapping and sampling program was undertaken over the new and existing electromagnetic (EM) anomalies highlighted in the most recent HTDEM geophysical survey. During the field program, a total of 213 rock samples and 343 soil samples were taken (Figure 1) and Ground FLTEM and borehole EM surveys were completed.

Key Highlights:

Ramp Metals is pleased to share key highlights from its ongoing exploration efforts and upcoming plans at its flagship Saskatchewan project:

- Ranger: Newly exposed shear zone located approximately 325m NE of the Ranger-001 discovery hole.

- Redridge: Newly identified 2.4 km long EM anomaly located approximately 5km south of Ranger. Heavily oxidized with excellent outcrop exposure.

- Rush: Ground FLTEM geophysical survey completed, and three (3) new satellite targets identified.

- Available Capital: Ramp Metals currently has more than $4.5 million in its treasury.

"Ramp has completed another successful exploration program, identifying several promising targets. A newly exposed NE-SW trending shear zone at Ranger could provide fresh insights into the area's gold sources. Additionally, Redridge shows tremendous potential, with multiple samples displaying malachite staining and peacock weathering. Once drill permits are secured, our team will launch an aggressive drilling program," commented Jordan Black, CEO of Ramp Metals.

Figure 1: Samples collected during 2025 field program

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_001full.jpg

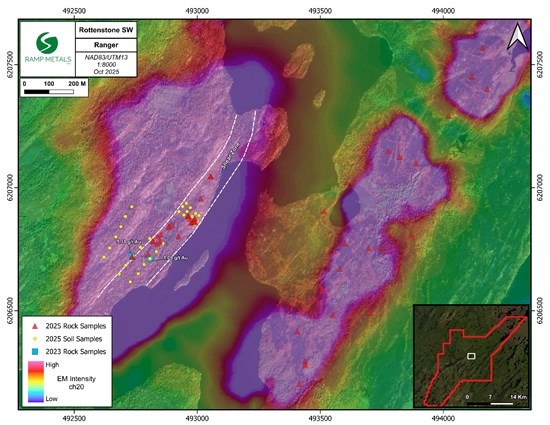

Ranger

As a result of the recently extinguished wildfires, teams were able to locate a newly exposed shear zone located approximately 325m NE of the Ranger-001 discovery hole (Figure 2). The NE-SW striking shear zone ranges from 50-70m wide and is covered by heavily oxidized soils with a deep red colour (Figure 3). A total of 30 soil and 29 rock samples were taken at Ranger. Sulphides were noted in strongly altered migmatite and mafic volcanic outcrops throughout the shear zone. Quartz veins were also found within the shear zone, with the largest being up to 1.5m wide (Figure 4).

Figure 2: Ranger samples and newly exposed shear zone

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_002full.jpg

Figure 3: Ranger soil sample showing rusty coloration in shear zone

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_rampfigure3.jpg

Figure 4: Quartz vein containing sulphides found at Ranger within shear zone, the largest being up to 1.5m wide

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_003full.jpg

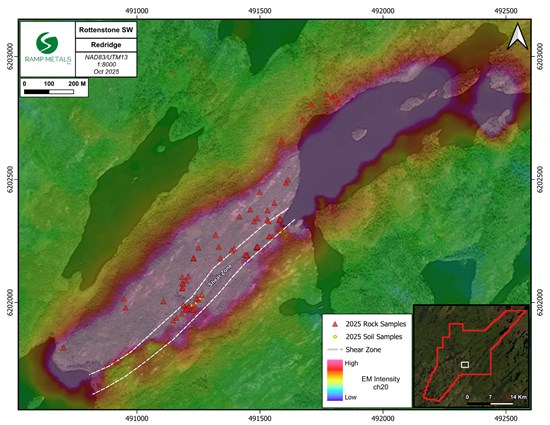

Redridge

Redridge is a newly identified 2.4 km long EM anomaly located approximately 5km south of Ranger (Figure 5). The anomaly was called "Redridge" due to the presence of a highly oxidized outcrop ridge (Figure 6), and red soils (Figure 7) found over a portion of the anomaly within the shear zone. The fires at Redridge revealed extensive outcrop exposure, enabling teams to identify altered mafic volcanic outcrops and scattered sub-angular boulders across the anomaly. Malachite staining, peacock weathering, and sulphides were observed in multiple samples. Additionally, a large shear zone was observed running NE-SW across the anomaly. A total of five (5) soil and 75 rock samples were taken at Redridge during the field program.

Figure 5: Redridge field program map

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_004full.jpg

Figure 6: The ridge for which the anomaly was named. Strongly altered, oxidized migmatite within the shear zone at 'Redridge'

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_005full.jpg

Figure 7: Soil sample 499049 from Redridge showing strong oxidation

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_ramp%20metals%20figure%206.jpg

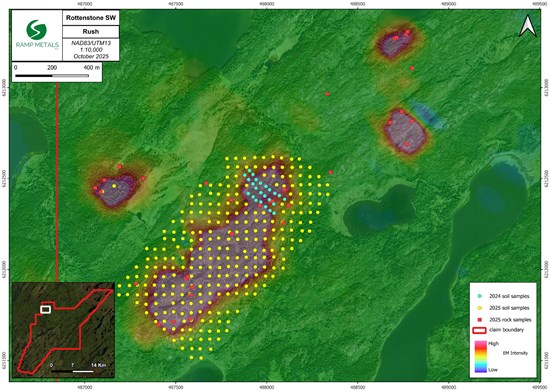

Rush

A soil grid was completed over the entire Rush anomaly at 50m spacing with teams prospecting while completing the soil grid. A total of 276 soil and 18 rock samples were taken over the main Rush anomaly (Figure 8). Additionally, three satellite anomalies located within 1 km of the main Rush anomaly were investigated. These anomalies show comparable rock types and alteration patterns to those observed at the surface of the primary Rush anomaly.

Dias Geophysical completed a ground FLTEM geophysical survey to cover the 1200m long main Rush anomaly. Borehole EM was also completed on Rush-001, 003, 006, 007, 008, 009, and 010.

Figure 8: Rush 2025 field sample map

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_007full.jpg

Rogue

Borehole EM was conducted on Rogue-001 and Rogue-002. In addition, a 100-meter grid with 30 soil samples was completed over the section of the Rogue anomaly that remained outside the coverage of the 2024 program (Figure 9). Even with the recent fire in the area, outcrop exposure over Rogue is extremely limited or nonexistent as till and topsoil covers the top 5-10m of the anomaly.

Figure 9: Samples taken at Rogue during field program

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_008full.jpg

Update on 2025 Drill Results

Ranger and Rogue

No significant gold values were intercepted in the remaining holes from the 2025 drill program at Ranger and Rogue. Drill holes returned anomalous gold values up to 0.143 g/t over 1m at Ranger. Despite this, the Company intends to continue gold exploration activities in the Ranger area, supported by promising results obtained from the recent 2025 fall field program.

All drill collar locations from the winter 2025 drill program can be found below in Table 1.

Table 1: All collars from the 2025 Drill Program. All coordinates are in NAD83/UTM Zone 13

| Hole Number | Azimuth | Dip | Depth (m) | Northing | Easting | Elevation (m) |

| Ranger-002 | 286 | -60 | 327 | 6206675 | 492758 | 437 |

| Ranger-003 | 316 | -70 | 317 | 6206675 | 492758 | 437 |

| Ranger-004 | 110 | -55 | 315 | 6206744 | 492682 | 446 |

| Ranger-005 | 142 | -75 | 350 | 6206837 | 492605 | 451 |

| Ranger-006 | 123 | -62 | 302 | 6206837 | 492605 | 451 |

| Ranger-007 | 155 | -60 | 302 | 6206837 | 492605 | 451 |

| Ranger-008 | 310 | -50 | 200 | 6207390 | 494201 | 433 |

| Rush-001 | 310 | -50 | 177 | 6212077 | 487855 | 475 |

| Rush-002 | 295 | -55 | 122.75 | 6212077 | 487855 | 475 |

| Rush-003 | 330 | -55 | 194 | 6212077 | 487855 | 475 |

| Rush-004 | 130 | -50 | 158 | 6212302 | 487923 | 485 |

| Rush-005 | 148 | -69 | 74 | 6212302 | 487923 | 485 |

| Rush-006 | 130 | -50 | 166 | 6212019 | 487627 | 477 |

| Rush-007 | 310 | -50 | 287 | 6212004 | 487781 | 479 |

| Rush-008 | 310 | -50 | 203 | 6211802 | 487573 | 470 |

| Rush-009 | 304 | -60 | 209 | 6212077 | 487855 | 475 |

| Rush-010 | 310 | -50 | 269 | 6212227 | 487930 | 460 |

| Rogue-004 | 141 | -50 | 301 | 6208716 | 489939 | 454 |

| Rogue-005 | 130 | -50 | 329 | 6207972 | 489501 | 430 |

| Rogue-006 | 130 | -50 | 338 | 6208330 | 489981 | 475 |

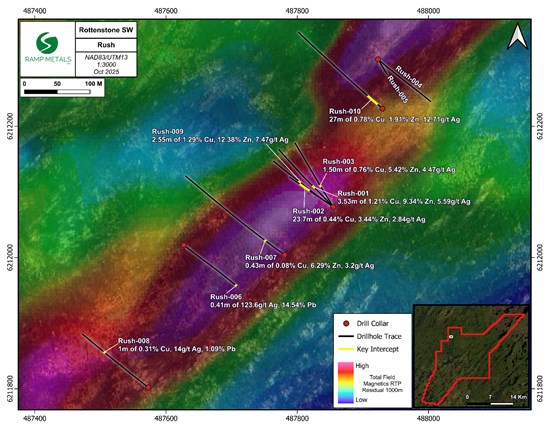

Rush

Mineralization was intersected in 8 out of 10 holes drilled at Rush during the drilling program. Table 2 below features key intercepts from the remaining drillholes at Rush. See Figure 10 for an overview of select key intercepts from Rush drilling to date. First pass drilling has shown that the interpreted VMS style mineralization can be found along the full length of the Rush anomaly. The Company believes that the relationship identified between the mineralized intercepts and the recently conducted FLTEM and BHEM surveys could inform and enhance targeting in future drilling programs.

Table 2: Rush - Key intercepts from the remainder of drillholes from the 2025 winter drill program

| Hole Number | From | To | Length (m) | Cu % | Zn % | Ag g/t | Au g/t | Pb % |

| Rush-006 | 81 | 82 | 1 | 0.10 | 0.03 | 1.2 | 0.01 | 0.005 |

| Rush-006 | 161 | 161.41 | 0.41 | 0.004 | 0.06 | 123.6 | 0.06 | 14.54 |

| Rush-007 | 55 | 56 | 1 | 0.10 | 0.28 | <0.5 | 0.01 | 0.02 |

| Rush-007 | 56 | 56.43 | 0.43 | 0.08 | 6.29 | 3.2 | 0.02 | 0.22 |

| Rush-008 | 135 | 136 | 1 | 0.31 | 0.04 | 14 | 0.02 | 1.09 |

Figure 10: Rush Drill holes - Select key Intercepts overlaying Total Field Magnetics RTP Residual 1000m

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_009full.jpg

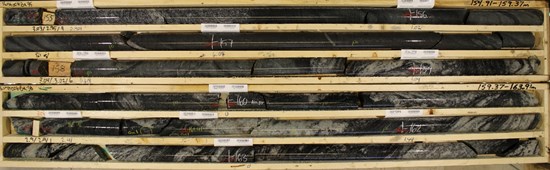

Figure 11: Rush-006 - Boxes 35 & 36; 154.91-163.91m

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_010full.jpg

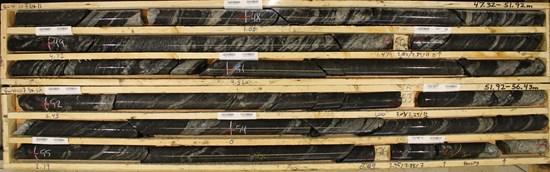

Figure 12: Rush-007 - Boxes 11 & 12; 47.32-56.43m

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/8725/271241_3abc37c1a419aad7_011full.jpg

Permits and Drilling

As mentioned in the August 5, 2025 New Release, the Company has submitted an amendment to its existing permits, requesting a two-year extension, authorization for an additional 30,000 metres of drilling, and approval to establish a temporary work camp. The Company will provide an update on the status of the amendment to the market once received.

QA/QC and Geochemical Sampling Procedure

All drill core samples were logged, photographed, and bagged on-site. All rock and soil samples were taken, described, photographed, and bagged on-site. Control samples consisting of certified reference samples and blank samples were systematically inserted into the sample stream and analyzed as part of the Companies QA/QC protocol at a rate of 1:15 or better. All samples were transported by Manitoulin Transport to Bureau Veritas Commodities Canada Ltd.("BV"), an internationally recognized and ISO 17025:2017 accredited analytical services provider, at its Vancouver, British Columbia laboratory. The Company's QA/QC protocol is in addition to BV's QA/QC standard procedure.

Drill core samples were prepared using the PRP70-250 package, where samples were weighed, dried, and crushed to greater than 70% passing a 2mm sieve, then pulverized to greater than 85% passing 75 microns. Samples from Rush and Rogue were analyzed in accordance with BV's FA330 (Au,Pt,Pd) and MA300 packages, for both gold, platinum & palladium analysis by fire assay (30g fire assay with AAS finish) and multi-element ICP analysis (0.25 g, multi-acid and ICP-ES analysis). Samples from Ranger were analyzed in accordance with BV's FA330-Au and MA300 packages, for gold by fire assay (30g fire assay with AAS finish) and multi-element ICP analysis (0.25 g, multi-acid and ICP-ES analysis). Gold returning >10ppm is automatically analyzed by gravimetric method in accordance with BV's standard of practice. Copper, zinc and lead over limits were re-assayed using BV's MA370 package, a multi-acid digestion with ICP-ES finish.

Rock and soil samples from this field program have been submitted to BV using the following packages and procedures:

Rock samples are prepared using the PRP70-250 package, where samples are weighed, dried, and crushed to greater than 70% passing a 2mm sieve, then pulverized to greater than 85% passing 75 microns. Samples are then analyzed in accordance with BV's FA330 and MA300 packages, for both gold, platinum and palladium analysis by fire assay (30g fire assay with AAS finish) and multi-element ICP analysis (0.25 g, multi-acid and ICP-ES analysis). Gold returning >10ppm is automatically analyzed by gravimetric method in accordance with BV's standard of practice.

Soil samples are prepared using BV's SS80 package, where samples are dried at 60°C and sieved to depletion to -180 µm (80 mesh). Samples are then analyzed in accordance with BV's AQ251+PGM package, an ultra-trace by ICP-MS analysis where aqua regia digestion is used for low to ultra-low determination on soils followed by a 37 element (including gold) ICP-MS with the platinum, palladium add on for analysis of a 15g sample.

Qualified Person

Brett Williams, P.Geo., VP Operations and Senior Geologist for Ramp Metals, and a "qualified person" under National Instrument 43-101 Standards of Disclosure for Mineral Projects, has reviewed and approved the technical content in this news release.

About Ramp Metals Inc.

Ramp Metals is a grassroots exploration company with a focus on a potential new Saskatchewan copper-gold district. The Company currently has a high-grade gold discovery of 73.55 g/t Au over 7.5m, and a new Cu-Zn-Pb-Ag VMS discovery at its flagship Rottenstone SW property. The Rottenstone SW property comprises 32,715 hectares and is situated in the Rottenstone Domain.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

FORWARD-LOOKING STATEMENTS

This news release contains "forward-looking statements" within the meaning of applicable securities laws. All statements contained herein that are not clearly historical in nature may constitute forward-looking statements. Generally, such forward-looking information or forward-looking statements can be identified by the use of forward-looking terminology such as "plans", "expects" or "does not expect", "is expected", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or "does not anticipate", or "believes", or variations of such words and phrases or may contain statements that certain actions, events or results "may", "could", "would", "might" or "will be taken", "will continue", "will occur" or "will be achieved". The forward-looking information and forward-looking statements contained herein include, but are not limited to, statements regarding the Company's exploration activities.

These statements involve known and unknown risks, uncertainties and other factors, which may cause actual results, performance or achievements to differ materially from those expressed or implied by such statements, including but not limited to: requirements for additional capital; future prices of minerals; changes in general economic conditions; changes in the financial markets and in the demand and market price for commodities; other risks of the mining industry; the inability to obtain any necessary governmental and regulatory approvals; changes in laws, regulations and policies affecting mining operations; hedging practices; and currency fluctuations.

Although the Company has attempted to identify important factors that could cause actual actions, events or results to differ materially from those described in forward-looking statements, there may be other factors that cause actions, events or results to differ from those anticipated, estimated or intended. Accordingly, readers should not place undue reliance on any forward-looking statements or information. No forward-looking statement can be guaranteed. Except as required by applicable securities laws, forward-looking statements speak only as of the date on which they are made and the Company does not undertake any obligation to publicly update or revise any forward-looking statement, whether as a result of new information, future events, or otherwise.

For further information, please contact:

Ramp Metals Inc.

Jordan Black

Chief Executive Officer

jordaneblack@rampmetals.com

Prit Singh

Director

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/271241

SOURCE: Ramp Metals Inc.