VANCOUVER, British Columbia, Feb. 04, 2026 (GLOBE NEWSWIRE) -- SAGA Metals Corp. ("SAGA" or the "Company") (TSXV: SAGA) (OTCQB: SAGMF) (FSE: 20H), a North American exploration company focused on critical mineral discoveries, is pleased to announce the assay results for the four (4) remaining diamond drill holes completed in Q4 2025 at the Trapper Zone's southern section known as "Trapper South". The Company initiated its maiden Mineral Resource Estimate ("MRE") drill program in late 2025 at the Trapper Zone with eight (8) total drill holes, four (4) in Trapper North and four (4) in Trapper South.

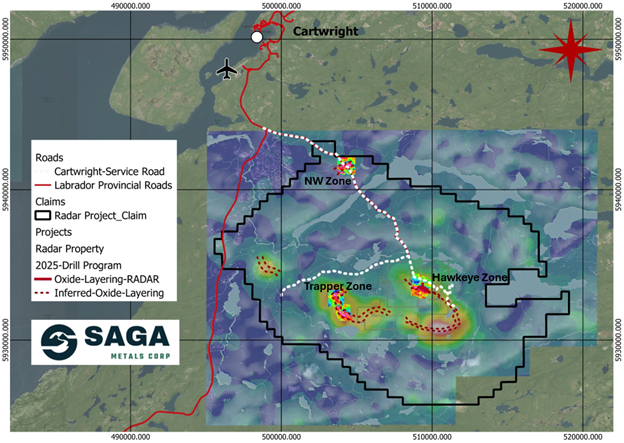

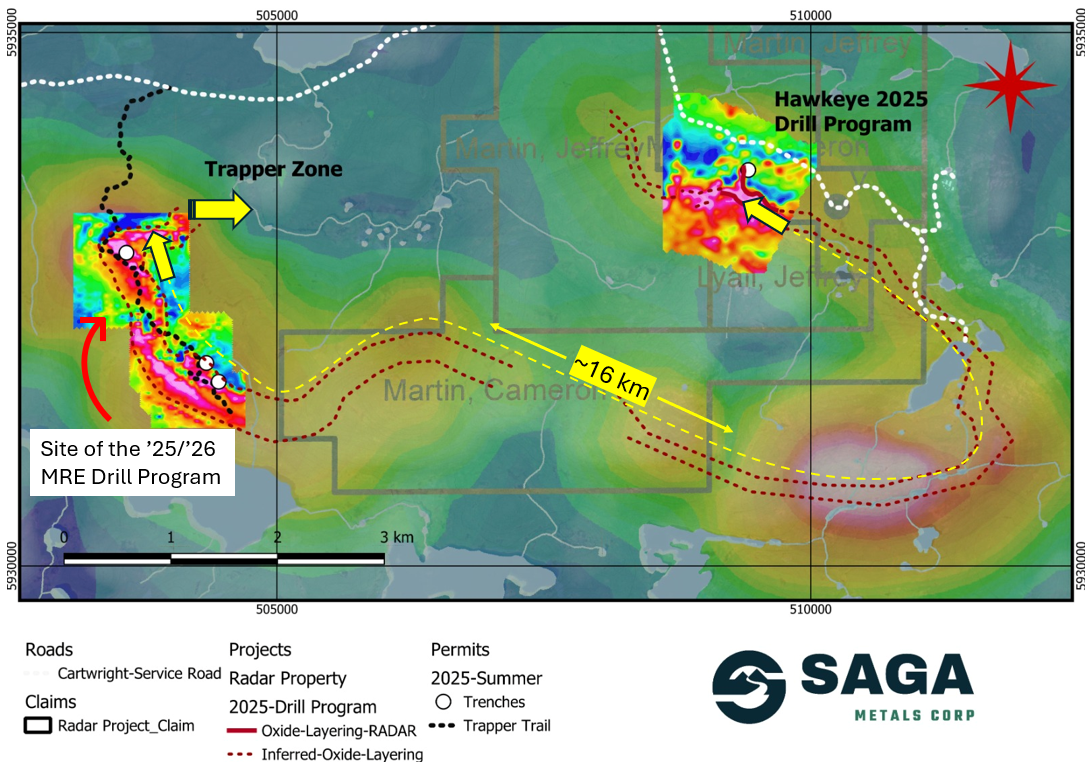

The Trapper Zone stretches over 3 km in the western part of the 100%-owned Radar Titanium-Vanadium-Iron property located near the port of Cartwright in Labrador, Canada.

Trapper South Assay Highlights

- Analytical results have now been obtained for all four (4) diamond drill holes in Trapper South and constitute eight (8) of eight (8) drill holes completed during the Q4 2025 Phase of the MRE drill program.

- Trapper South analytical results to-date include numerous oxide-rich intercepts, including:

- R-0015: 100.70 m grading 38.56% Fe2O3, 6.8% TiO2, and 0.229% V2O5

- R-0014: 41.20 m grading 36.17% Fe2O3, 6.36% TiO2, and 0.188% V2O5

- R-0013: 111.50 m grading 37.08% Fe2O3, 5.14% TiO2, and 0.242% V2O5

- R-0012: 75.20 m grading 27.39% Fe2O3, 4.87% TiO2, and 0.116% V2O5

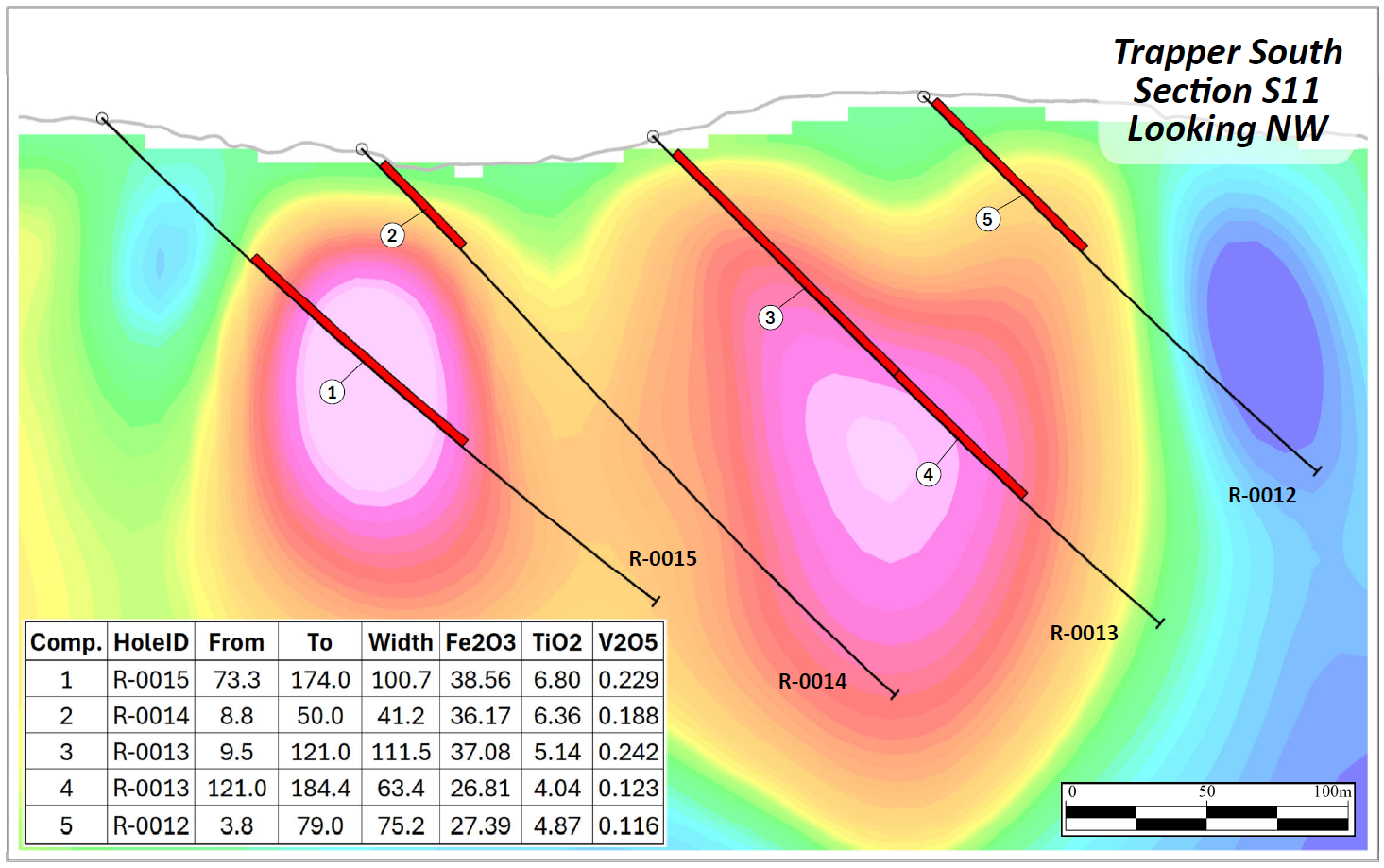

- Cross section S-11 included all four (4) drill holes R-0015, -0014, -0013, and -0012.

- Continued consistency of rhythmic banding and an increase in overall oxide concentration in Trapper vs Hawkeye Zone.

Cross section of Trapper South S11 Summary

- R-0015: The oxide zone starts at 77 m with some isolated rafted massive oxide mineralization associated with shearing starting at 73.3 m and continues consistently without major interruptions until 232 m. The featured composite in this hole is from 73.3 m to 174 m of Fe2O3: 38.565%; TiO2: 6.79%, and V2O5: 0.229% for 100.70 m.

- R-0014: The individual oxide layers in this drill hole from 8 m to 106 m are up to 30 cm thick. A 41.2m oxide zone from 8.8 m to 50 m is the highlighted composite of Fe2O3: 36.17%; TiO2: 6.36%, and V2O5: 0.188%.

- R-0013: Drilling in R-0013 contains an oxide zone over a total of 180 m, with a highlighted composite of Fe2O3: 37.08%; TiO2: 5.14%, and V2O5: 0.242% for the first 111.50 m from 9.5 to 121 m.

- R-0012: The oxide zone is encountered in the first 80 m of the hole with highlighted composite at 75.20 m of Fe2O3: 27.39%, TiO2: 4.87%, and V2O5: 0.116% from 3.8 m to 79 m.

| DDH | FROM | TO | Length | Fe2O3 | TiO2 | V205 | ||

| ID | m | m | m | - | - | - | ||

| R-0015 | 73.3 | 174 | 100.70 | 38.56 | 6.80 | 0.229 | ||

| R-0014 | 8.8 | 50 | 41.20 | 36.17 | 6.36 | 0.188 | ||

| R-0013 | 9.5 | 121 | 111.50 | 37.08 | 5.14 | 0.242 | ||

| R-0012 | 3.8 | 79 | 75.20 | 27.39 | 4.87 | 0.116 | ||

Table 1: Assay results and composites of R-0015, -0014, -0013 and -0012 from Trapper South.

Figure 1: Cross section S11 looking northwest, highlighting high-grade intercepts in holes R-0015, -0014, -0013, and -0012 with the 3D magnetic Inversion of the 2025 Trapper Zone ground magnetic survey.

Both R-0015 and R-0013 are near-complete intercepts of oxide layering through the magnetic anomaly, as shown in Figure 1 above. All four drill holes on cross section S11 were collared from the East (starting at R-0012) to the West (ending with R-0015) and, as expected, show an increase of oxide mineralization through each of the limbs. Drills were collared directly into oxide on the surface in an effort to maintain a consistent 100 m spacing between holes. Further to the Company's news release dated December 17, 2025, drill hole R-0014 drilled oxide mineralization for 41.2 m near surface and also provided valuable insights into the two major magnetic anomalies (eastern and western anomalies). The remainder of R-0014 confirmed the presence of reverse faults, suggesting that the two anomalies (East and West) were initially connected but have since been separated by a combination of folding and faulting, specifically a left-lateral strike-slip reverse fault.

The rhythmic banding oxide sequences observed in Trapper South's S11 cross-section are reminiscent of the Hawkeye Zone drill program completed in Q1 2025. This indicates exceptional consistency and continuity between the two zones, which extend for 16 km in strike length.

2026 Phase of Trapper Zone MRE Drill Program is Underway:

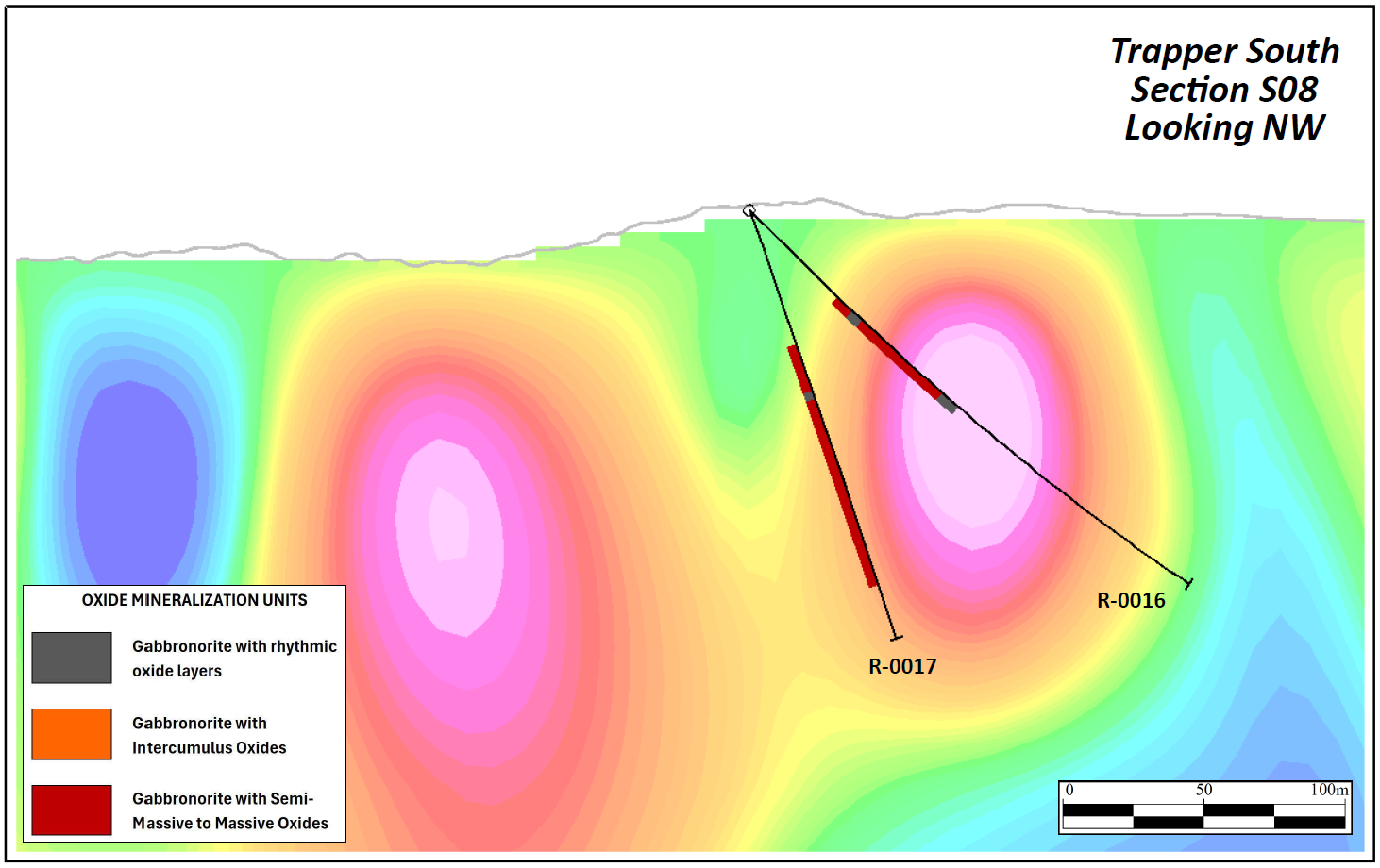

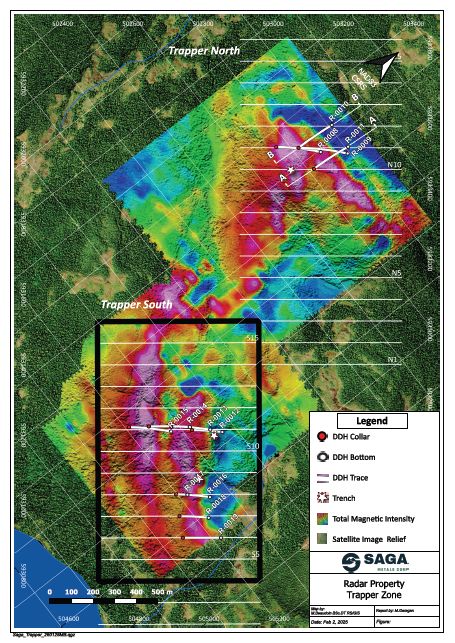

Further to the Company's news release, dated January 29, 2026, the 2026 phase of MRE drilling commenced with R-0016 and has already progressed to its fourth hole (R-0019). After recording observed rhythmic banding in cross-section S11 (as reported above), the team had expected to see the same consistency throughout the extent of Trapper South. However, the team was positively impressed by intercepting 60-90 m of semi-massive to massive oxide in two (2) drill holes of cross-section S8 (R-0016 & R-0017), as well as further semi-massive to massive oxide in cross-section S7 (see cross section S8 below in Figure 2). As drilling in Trapper South continues, Saga's geological team can map and plan for pockets of increased concentrations of oxide mineralization, which correlates to the exceptional VTM and ilmenite mineralization as shown by assay results in Trapper North.

The core economic target remains these extensive, continuous bodies of semi-massive to massive oxide mineralization-that have consistently delivered exceptional grades of titanium, vanadium, and iron. Identifying these broad oxide zones in Trapper South could potentially compound the Company's expectation on grade, thickness, continuity, and geometry, across the entire Trapper Zone, paving the way for a robust mineral resource definition.

Figure 2: Cross section S8 showing R-0016 and -0017 with the 3D Magnetic Inversion of the 2025 Trapper Zone ground magnetic survey.

Michael Garagan, CGO & Director of Saga Metals commented: "The final 2025 assay results from Trapper South have delivered exceptional grades across all four drill holes, with standout intercepts that rival the rhythmic banding observed at the Hawkeye zone in early 2025. These results further validate the continuity of oxide mineralization along the 16+ km strike from Hawkeye to Trapper. In 2026 drilling to-date, our geological team has identified significant oxide concentrations in both S8 and S7 cross sections in Trapper South. This accumulation of semi-massive to massive mineralization was not expected outside of Trapper North and now increases the likelihood of additional thick, high-grade oxide layering throughout the 3+ km strike length of the Trapper Zone."

Figure 3: Trapper Zone map outlining location of the initial 2026 focus for the remainder of the MRE drill program to be completed in 2026, updated with cross-section S8 and S7, showing the TMI of the 2025 Trapper Zone ground magnetic survey. Drilling will commence in Trapper South and move to Trapper North.

Figure 4: 25-tonne excavator moving the drill shack into position on drill hole R-0018.

Key Project Highlights:

- Confirmed mineralization in 15 out of 15 drill holes completed in two primary zones to-date.

- Analytical results to-date include numerous oxide-rich intercepts, including:

| DDH | FROM | TO | Length | Fe2O3 | TiO2 | V205 | ||

| ID | m | m | m | - | - | - | ||

| R-0009 | 94 | 181.2 | 87.20 | 50.67 | 10.15 | 0.339 | ||

| R-0008 | 170 | 237.6 | 68.26 | 46.15 | 9.21 | 0.311 | ||

| R-0010 | 1.5 | 137 | 135.50 | 50.03 | 7.87 | 0.352 | ||

| R-0015 | 73.3 | 174 | 100.70 | 38.56 | 6.80 | 0.229 | ||

| R-0011 | 58.1 | 153.3 | 95.15 | 39.49 | 6.49 | 0.222 | ||

| R-0014 | 8.8 | 50 | 41.20 | 36.17 | 6.36 | 0.188 | ||

| R-0007 | 147.5 | 205.2 | 57.70 | 27.09 | 5.31 | 0.365 | ||

Table 2: Top 7 intercepts from the 2025 drilling programs at both Trapper and Hawkeye Zones

- Infrastructure including road access, deep-water port, nearby hydro-electric power and airstrip.

- Confirmed the 16+ km oxide layering trend that stretches from the Hawkeye Zone to the Trapper Zone.

- Exceptional grades and thicknesses with semi-massive to massive oxide reporting up to 64.55% Fe,13.3% TiO2, and 0.66% V2O5.

- Petrographic analysis confirms titanomagnetite mineralization is advantageous for simplified metallurgical processing.

About the Radar Critical Mineral Property in Labrador

The Radar Property spans 24,175 hectares and hosts the entire Dykes River intrusive complex (~160 km²), a unique position among Western explorers. Geological mapping, geophysics, and trenching have already confirmed oxide layering across more than 20 km of strike length, with mineralization open for expansion.

Figure 5: Radar Property map, depicting magnetic anomalies, oxide layering and the site of the 2025 drill programs. The Property is well serviced by road access and is conveniently located near the town of Cartwright, Labrador. A compilation of historical aeromagnetic anomalies is overlaid by ground-based geophysics, as shown.

Vanadiferous titanomagnetite ("VTM") mineralization at Radar is comparable to global Fe-Ti-V systems such as Panzhihua (China), Bushveld (South Africa), and Tellnes (Norway), positioning the Project as a potential strategic future supplier of titanium, vanadium, and iron to North American markets.

Figure 6: Radar Project's prospective oxide layering zone validated over ~16 km strike length through Fall 2025 drilling, as shown on a compilation of historical airborne geophysics as well as ground-based geophysics in the Hawkeye and Trapper zones completed by SAGA in the 2024/2025 field programs. SAGA has demonstrated the reliability of the regional airborne magnetic surveys after ground-truthing and drilling in the 2024 and 2025 field programs.

Qualified Person

Paul J. McGuigan, P. Geo., is an Independent Qualified Person as defined under National Instrument 43-101 and has reviewed and approved the technical information disclosed in this news release.

Technical Information

Samples were cut by Company personnel at SAGA's core facility in Cartwright, Labrador. Diamond drill core was sawed and then sampled intervals. The drill hole core diameter utilized was NQ.

Core samples have been prepared and analyzed at the Impact Global Solutions (IGS) laboratory facility in Montreal, Quebec. Blanks, duplicates, and certified reference standards are inserted into the sample stream to monitor laboratory performance. Crush rejects, and pulps are kept and stored in a secure storage facility for future assay verification. The Company utilizes a rigorous, industry-standard QA/QC program.

About SAGA Metals Corp.

SAGA Metals Corp. is a North American mining company focused on the exploration and discovery of a diversified suite of critical minerals that support the North American transition to supply security. The Radar Ti-V-Fe Project comprises 24,175 hectares and entirely encloses the Dykes River intrusive complex, mapped at 160 km² on the surface near Cartwright, Labrador. Exploration to date, including 4,250 m of drilling, has confirmed a large, mineralized layered mafic intrusion hosting vanadiferous titanomagnetite (VTM) and ilmenite mineralization with strong grades of titanium and vanadium.

The Double Mer Uranium Project, also in Labrador, covers 25,600 hectares and features uranium radiometrics that highlight an 18km east-west trend, with a confirmed 14km section producing samples as high as 0.428% U3O8. Uranium uranophane was identified in several areas of highest radiometric response (2024 Double Mer Technical Report).

Additionally, SAGA owns the Legacy Lithium Property in Quebec's Eeyou Istchee James Bay region. This project, developed in partnership with Rio Tinto, has been expanded through the acquisition of the Amirault Lithium Project. Together, these properties cover 65,849 hectares and share significant geological continuity with other major players in the area, including Rio Tinto, Winsome Resources, Azimut Exploration, and Loyal Metals.

With a portfolio spanning key commodities critical to the clean energy future, SAGA is strategically positioned to play an essential role in critical mineral security.

On Behalf of the Board of Directors

Mike Stier, Chief Executive Officer

For more information, contact:

Rob Guzman, Investor Relations

SAGA Metals Corp.

Tel: +1 (844) 724-2638

Email: rob@sagametals.com

www.sagametals.com

Neither the TSX Venture Exchange nor its Regulation Service Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Disclaimer

This news release contains forward-looking statements within the meaning of applicable securities laws that are not historical facts. Forward-looking statements are often identified by terms such as "will", "may", "should", "anticipates", "expects", "believes", and similar expressions or the negative of these words or other comparable terminology. All statements other than statements of historical fact, included in this release are forward-looking statements that involve risks and uncertainties. In particular, this news release contains forward-looking information pertaining to the Company's Radar Project and IR agreements listed herein. There can be no assurance that such statements will prove to be accurate and actual results and future events could differ materially from those anticipated in such statements. Important factors that could cause actual results to differ materially from the Company's expectations include, but are not limited to, changes in the state of equity and debt markets, fluctuations in commodity prices, delays in obtaining required regulatory or governmental approvals, environmental risks, limitations on insurance coverage, inherent risks and uncertainties involved in the mineral exploration and development industry, particularly given the early-stage nature of the Company's assets, and the risks detailed in the Company's continuous disclosure filings with securities regulations from time to time, available under its SEDAR+ profile at www.sedarplus.ca. The reader is cautioned that assumptions used in the preparation of any forward-looking information may prove to be incorrect. Events or circumstances may cause actual results to differ materially from those predicted, as a result of numerous known and unknown risks, uncertainties, and other factors, many of which are beyond the control of the Company. The reader is cautioned not to place undue reliance on any forward-looking information. Such information, although considered reasonable by management at the time of preparation, may prove to be incorrect and actual results may differ materially from those anticipated. Forward-looking statements contained in this news release are expressly qualified by this cautionary statement. The forward-looking statements contained in this news release are made as of the date of this news release and the Company will update or revise publicly any of the included forward-looking statements only as expressly required by applicable law.

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/af448699-9b74-4426-a644-07eae44363ff

https://www.globenewswire.com/NewsRoom/AttachmentNg/12480453-a2fa-40de-b191-dc4aeebea9f5

https://www.globenewswire.com/NewsRoom/AttachmentNg/15768702-9513-44f0-8b27-b18c0ae25d19

https://www.globenewswire.com/NewsRoom/AttachmentNg/f6e914c1-ff2a-4944-81da-9b501fa12e9a

https://www.globenewswire.com/NewsRoom/AttachmentNg/799436b0-eb3c-4243-ae10-d1e2e2b08058

https://www.globenewswire.com/NewsRoom/AttachmentNg/536d401d-9416-48cd-8d2f-cb3cc92db7c3