Third quarter production decreases in difficult market; Long-term outlook improving

Third Quarter 2025

· Revenue for Period: SEK 23.5 million (SEK 32.6 million). Recurring revenue accounted for 87.1% (92.3%) of the revenue

· Operating Result: SEK 5.6 million (SEK 13.2 million), yielding 23.8% (40.4%) operating margin

· Earnings per Share: SEK 0.62 per share (SEK 1.45 per share)

· Cashflow from Operations: SEK 12.4 million (SEK 14.6 million), outpacing operating result primarily due to decreased operating receivables

· Series production begins at new Scania facility in China

· System 4000 installation completed at Maringá Soldas in Brazil

· Ian Kershaw elected as Chairman at Extraordinary General Meeting on 30 September 2025

Year-to-Date 2025

· Revenue for Period: SEK 81.7 million (SEK 99.8 million). Recurring revenue accounted for 92.9% (94.5%) of the revenue

· Operating Result: SEK 27.0 million (SEK 33.7 million), yielding 33.1% (33.8%) operating margin

· Earnings per Share: SEK 2.95 per share (SEK 3.80 per share)

· Cashflow from Operations: SEK 33.5 million (SEK 46.4 million), primarily due to decreased operating results, reduced operating liabilities and reduction in prior-year operating receivables

· Dividend: Ordinary dividend of SEK 6.00 per share (SEK 5.50 per share) and extraordinary dividend of SEK 1.00 per share (SEK 0.60 per share), equivalent to SEK 49.5 million (SEK 43.1 million), to be paid in two equal instalments. Record date 7 November 2025 for second payment

· Installed Base: 58 (57) installations, 26 (26) fully automated systems, 24 (23) mini-systems and eight (eight) tracking systems in 13 (12) countries

CEO Message

Weak demand impacts commercial vehicle sales; passenger vehicles remain strong

Series production in the third quarter finished at 2.7 million Engine Equivalents, representing a 17% decrease compared to the first half of the year (3.25 million Engine Equivalents) and a 23% decrease compared to the year-ago quarter (3.5 million Engine Equivalents). The year-on-year decrease was primarily due to a 33% reduction in commercial vehicle production that impacted volume by 570,000 Engine Equivalents, extended summer shutdowns at most customer sites, and the historical loss of 400,000 Engine Equivalents from the stoppage of a high volume programme in September 2024. In contrast to these headwinds, the current programmes in the passenger vehicle and off-road sectors delivered strong growth during the third quarter, providing a combined year-on-year increase of 150,000 Engine Equivalents, representing 11% growth.

At the outset of the year, we predicted strong growth in 2025, benefitting from the transition to the new Traton Group common engine at MAN, start of production (SOP) of a new engine family at First Automobile Works (FAW), and a commercial vehicle pre-buy in advance of EPA 2027 in the United States. However, in the face of weak demand and global market uncertainty, MAN has extended production of its previous generation engine, FAW has deferred SOP, and the pre-buy effect has been negated by the Trump administration's suspension of EPA 2027. While the current development is challenging, the long-term outlook continues to grow; we are experiencing a slowdown, not a change of direction. When the current cycle ends, there will be a convergence of positive factors for SinterCast, including pent-up demand for fleet renewal, a strong ramp of the delayed programmes, and the start of production of more than 500,000 Engine Equivalents of new orders received during the first half of 2025. We remain steadfast that every commercial vehicle OEM will adopt CGI before the end of the decade and that this trend will drive growth to the five and six million Engine Equivalent milestones, and beyond. However, it is expected that the current market slowdown will push our timeline for reaching the five million Engine Equivalent milestone into 2027, compromising our previous target of reaching the milestone before the end of 2026.

The lower volume in the third quarter translated into a 28% decrease in year-on-year revenue, to SEK 23.5 million (SEK 32.6 million). Revenue was equally impacted by a 28% reduction in sales of the consumable Sampling Cup to 37,600 units (51,825) as foundry customers adjusted inventories during the quarter. For the year-to-date period, revenue amounted to SEK 81.7 million (SEK 99.8 million), with 92.9% (94.5%) of the total revenue accounted for by recurring revenue. The recurring revenue is derived from the Production Fee levied for each Engine Equivalent, consumables and software licence fees. Benefitting from proactive cost reduction activities, the year-to-date operating result finished at SEK 27.0 million (SEK 33.7 million), providing an operating margin of 33.1% (33.8%).

During October, Scania started production at its new commercial vehicle facility in Rugao, China. As with all other Scania production, the engines used at the Chinese facility rely on the SinterCast process control technology for the production of the Compacted Graphite Iron cylinder blocks and heads. Scania announced a production target of 10,000 vehicles in 2026 (85,000 Engine Equivalents). The Rugao facility has been designed for the production of up to 50,000 commercial vehicles per year, which could provide approximately 425,000 Engine Equivalents per year at mature volume.

Brazilian tariffs, interrupted Ford F-150 production not impacting SinterCast

While tariffs have started to impact commercial vehicle sales, the unilateral tariffs applied by the Trump administration on Brazilian goods have not had a direct impact on SinterCast. Much of Tupy's production that is destined for the US is produced in Mexico, and as such, is protected under the current USMCA free trade agreement. Only 3% of the total SinterCast volume is produced in Brazil for direct export to the United States. Considering the costs and leadtimes required to re-source complex engineering components, the SinterCast-CGI production in Brazil is not considered to be under immediate threat. The new 25% tariff on commercial vehicles and commercial vehicle components, implemented with effect from 1 November 2025, is applied equally to all non-USMCA countries. While this new tariff may further burden commercial vehicle sales, it will not apply the SinterCast production in Mexico and it will not impose an unbalanced trading disadvantage on any particular country. As there are no cast iron cylinder block and head foundries in the United States, the US must import 100% of its cast iron cylinder blocks and heads. The main sources are Mexico and Brazil, with some components coming from Europe and none, as yet, from Asia. Considering the need to import cast iron cylinder blocks and heads, the tariffs are not expected to change the foundry sourcing landscape.

During October, Ford announced that a fire at a Tier I supplier may interrupt production of the F-150 pick-up truck and other Ford models that use aluminium body components from the supplier. While vehicle production may be affected at the Ford vehicle assembly facilities in Michigan and Missouri during the fourth quarter, there have been no indications of reduced engine orders for the SinterCast-CGI base engine assembled at the Ford engine plant in Ohio. As the best-selling truck in America, F-150 vehicle assembly will eventually increase to recover demand. It is expected that the foundry production of the SinterCast-CGI cylinder block in Mexico, and of the 2.7 litre V6 petrol engine in Ohio, will continue at pace in the meantime.

Installation activity increasing toward year-end

Installation activity took a step forward in the third quarter, with equipment revenue of SEK 2.9 million (SEK 2.2 million). The third quarter benefitted from the System 4000 installation at the Maringá Soldas foundry in Brazil and strong aftermarket sales of spare parts. Installation activities are scheduled to intensify in the fourth quarter with the Mini-System 4000 installation at the Qingdao Surefire foundry in China, a capacity expansion at an undisclosed foundry partner in advance of increased commercial vehicle production, and continued aftermarket sales. With two months to go, our target is to reach SEK 10 million in full-year installation revenue. Discussions for new installations remain strong, despite increased caution for new capital expenditure. We expect to exceed our historical full-year average installation revenue of SEK 8 million again in 2026.

This report has been reviewed by the company's Auditors.

Stockholm 5 November 2025

For further information please contact:

Dr. Steve Dawson

President & CEO

SinterCast AB (publ)

Office: +46 150 794 40

Mobile: +44 771 002 6342

e-mail: steve.dawson@sintercast.com

website: www.sintercast.com

Corp. Id. 556233-6494

This press release contains information SinterCast AB (publ) is obliged to make public pursuant to the EU Market Abuse Regulation. This information was submitted for publication, through the agency of the President & CEO Dr. Steve Dawson, at 08:00 CET on 5 November 2025.

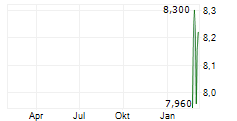

SinterCast is the world's leading supplier of process control technology for the reliable high volume production of Compacted Graphite Iron (CGI). Stronger, stiffer and more durable than conventional iron, CGI enables the development of smaller, lighter and more fuel efficient engines in passenger vehicle, commercial vehicle and industrial power applications. The use of SinterCast-CGI currently contributes to the reduction of approximately ten million tonnes of CO2 per year. With 58 installations in 13 countries, SinterCast provides sustainable solutions for manufacturing and transportation to the global foundry and automotive industries. SinterCast is a publicly traded company, quoted on the Small Cap segment of the Nasdaq Stockholm stock exchange (SINT). For more information: www.sintercast.com