Mineralized Porphyry Dyke Swarm Tagged Across Greater than 1km of Strike Length

TORONTO, ON / ACCESS Newswire / June 26, 2025 / Sterling Metals Corp. (TSXV:SAG)(OTCQB:SAGGF) ("Sterling" or the "Company") is pleased to announce results from the remaining three holes of the four diamond drill holes (CH-25-01, MJ-25-02 and MJ-25-03) recently completed at the Soo Copper Project ("Soo Copper" or the "Project") located in Batchewana Bay, Ontario. The holes have expanded on the high-grade copper zone intersected in the first hole (MJ-25-01) and successfully demonstrate the presence of a large, well-mineralized copper-molybdenum-silver-gold ("Cu-Mo-Ag-Au") porphyry system.

Highlights:

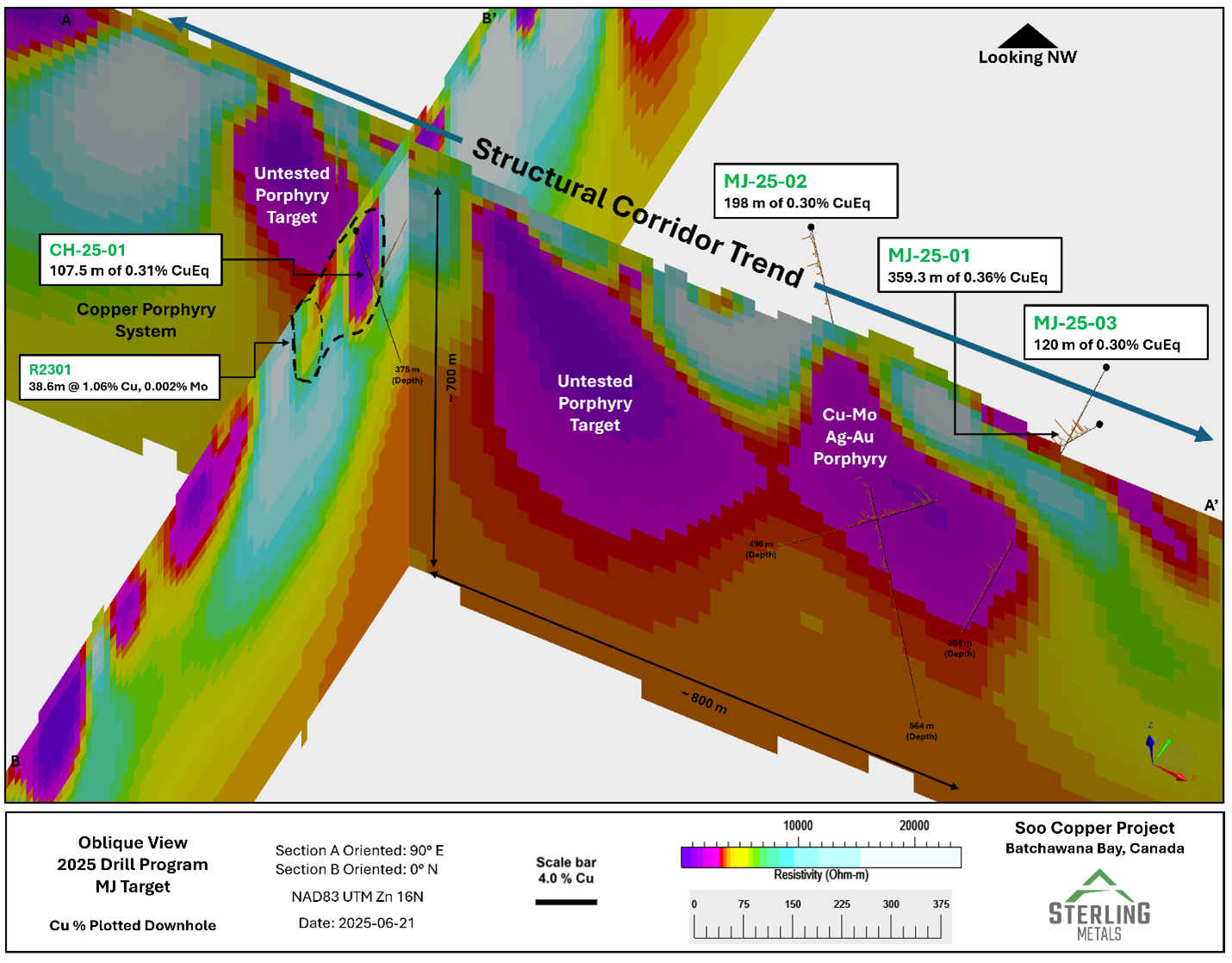

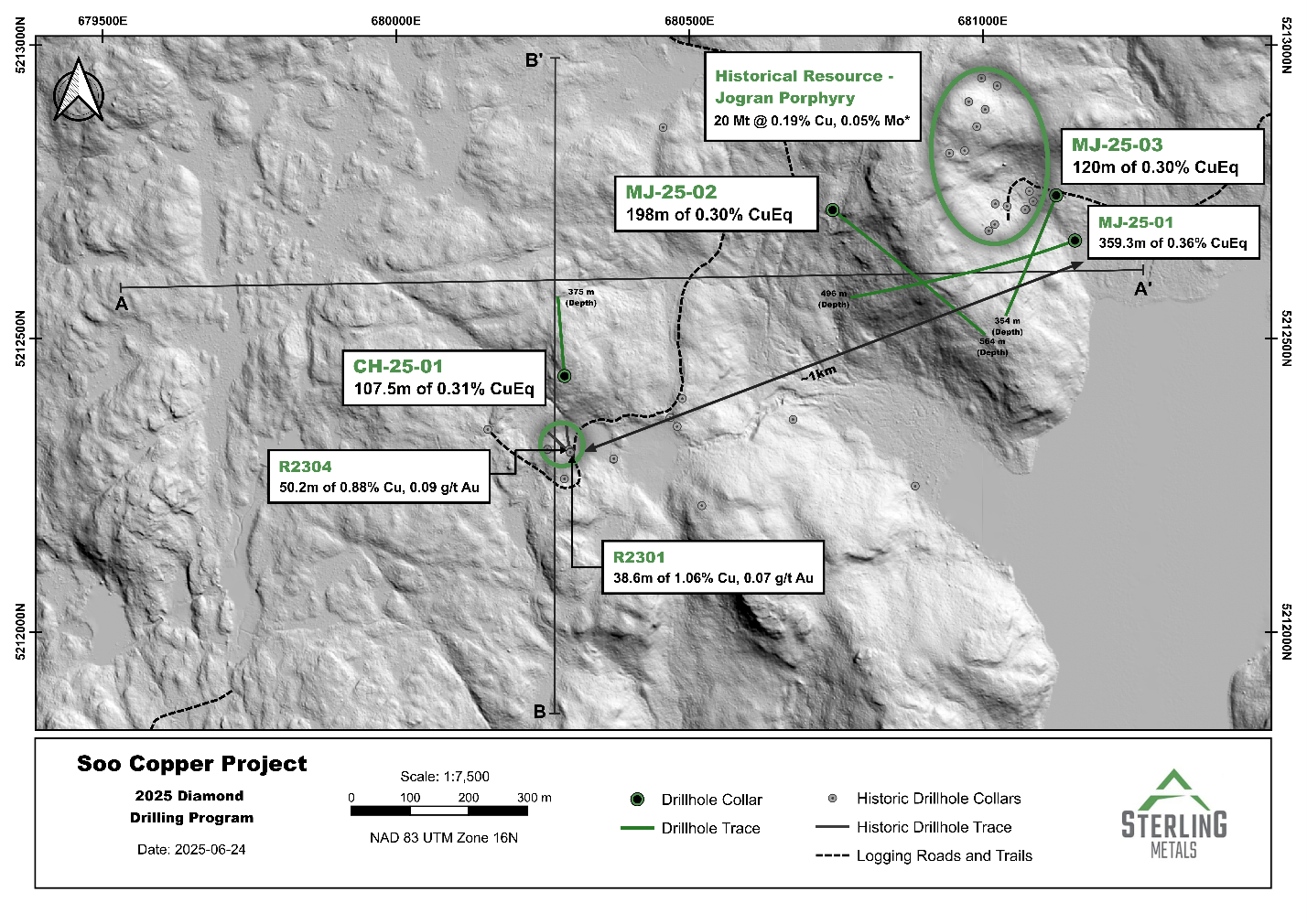

All four holes from the inaugural drill program intersected extensive porphyry copper mineralization (Figures 1 and 2).

The mineralized structural corridor has now been traced over 1km of strike and more than 300m vertically from surface and remains open in all directions (See Figure 2).

Hole CH-25-01 was drilled into a resistivity low approximately 1km from previously reportedMJ-25-01 (0.36% Copper Equivalent ("CuEq") over 359m including 0.56% CuEq over the first 75m of this interval ) and 200m from historic drill holes R2301 (38.6m of 1.06% Cu and 0.07 g/t Au) and R2304 (50.2m of 0.88% Cu and 0.09 g/t Au), and intersected 107.5m grading 0.31% CuEq, including 30.3m at 0.74% CuEq.

Follow up holes MJ-25-02 and MJ-25-03 intersected long mineralized intervals, including 198m grading 0.30% CuEq in MJ-25-02 and 120m grading 0.30% CuEq in MJ-25-03, indicating the presence of an extensive mineralized structure related to the emplacement of a large, well-mineralized porphyry system.

The strongest copper mineralization is associated with a 3-phase porphyry dyke swarm ("GFP Porphyry"), indicating a highly permeable, magmatic-hydrothermal structural corridor (See Table 1: Bornite 1,2, and 3).

Highest copper concentrations are consistently associated with permeable pathways in the host rocks; future drilling will focus on targeting high-permeability zones along the structural corridor, particularly zones of mineralized breccias.

The Company is working towards initiating its next drill program anticipated to commence in the next eight weeks.

Jeremy Niemi, Senior Vice President Exploration and Evaluation stated, "Intersecting extensive copper mineralization in all four holes, including a 1km step-out, has exceeded our expectations for this inaugural program. These results confirm the scale of the system and reinforce the potential for high-grade zones. Our next phase of drilling will build on this momentum, with a focus on targeting high-grade copper zones within permeable rocks near the newly discovered GFP porphyry."

Figure 1. 3D View of perpendicular cross sections showing trace of 2025 holes, mineralization and resistivity from Dias 3D IP survey in the background which matches porphyry alteration and mineralization.

Figure 2. Hole locations from Sterling Metals inaugural drilling at the Soo Copper Project.1

Important Geological Observations in CH-25-01, MJ-25-02 and MJ-25-03

Extensive copper-rich sulphide mineralization intersected in maiden program, with higher grades associated with the GFP porphyry dyke swarm which was intersected in all three MJ holes.

The GFP porphyry dyke swarm is interpreted to have an approximate east-west trend, which follows a structural corridor and coincides with several geophysical resistivity-low target areas.

All four holes display strong correlation between the 3D-IP survey resistivity low targets and porphyry copper mineralization and related alteration.

Mineralization, so far, is primarily chalcopyrite with locally abundant bornite with generally minor or no pyrite suggesting an extensive, well preserved, very copper-rich, potassic altered porphyry core zone is present in the target area.

Molybdenite is commonly found with chalcopyrite with evidence for particularly molybdenite-enriched zones.

Higher copper grades are clearly associated with zones of higher permeability that are marked by shear foliation, brecciation and the presence of porphyry dykes, of which the earliest pre-mineral phase (GFP Porphyry) exhibits very strong "EB", "A" and "B" type stages of porphyry veining.

The second hole of the program, CH-25-01, was collared approximately 1km west of MJ-25-01, targeting a discrete resistivity low located ~200 m north of the historic Richards Breccia prospect. The anomaly, similar in size and shape to the resistivity low at Richards, was initially interpreted as a potential breccia target. However, the hole remained largely in mafic volcanic rocks with disseminated chalcopyrite and pyrite, suggesting it intersected the outer edge of a larger porphyry system rather than the core of an isolated, smaller porphyry breccia. Importantly, the primary resistivity trend-associated with a structural corridor-lies to the north of this hole and extends both east and west (See Figure 1).

Follow-up holes to MJ-01-25 was designed to cross-cut the newly discovered bornite-bearing zones associated with the GFP Porphyry and to better understand the orientation of this high-grade copper mineralization. MJ-25-02 was drilled southeastward and intersected the GFP Porphyry dyke at a depth of approximately 254m. Notably, the surrounding mafic volcanics display a marked increase in bornite content and grade (38m grading 0.59% CuEq from 234m depth - Bornite 1), and-as seen in the initial discovery hole-there is a high copper tenor with minor to no pyrite present with chalcopyrite and bornite. These sheared, iron-rich mafic volcanics, interpreted as permeable and chemically reactive, appear to be an ideal host for copper sulphide mineralization adjacent to the porphyry which marks the original copper fluid pathway to the underlying source porphyry. Toward the end of the hole, molybdenum concentrations notably increased within a zone of magmatic hydrothermal brecciation, as, for example, an 83m interval grading 396 ppm Mo encountered towards the end of the hole. This mineralized breccia may indicate the toe of this hole was approaching another mineralized, porphyry-related structure just to the south of the hole.

The final hole of the program, MJ-25-03, was drilled from the side of an access road prior to the spring melt. Located approximately 300m east of MJ-25-02 and 100m north of MJ-25-01, this hole tested the eastern side of the potential east-west trend of the GFP Porphyry dyke and successfully intersected both the targeted dyke at 236m depth and extensive copper sulphide mineralization, primarily as chalcopyrite. With intersections in all three holes at the MJ target, the Company interprets a GFP Porphyry dyke swarm that was emplaced along an east-west structure that aligns closely with the 3D-IP resistivity data.

Approximately 500 metres west of the MJ holes, is the centre of a large, similar resistivity low which is planned for testing in the next phase of drilling. This anomaly potentially represents the western extension of the east-west trending mineralized structural corridor that hosts the GFP porphyry dyke swarm.

Table 1.Mineralization intervals for the remaining three holes of the four-diamond drill hole program.

Hole | From (m) | To (m) | Length (m) | Cu (%) | Mo (ppm) | Au (g/t) | Ag (g/t) | CuEq (%) |

|

|

|

|

|

|

|

|

|

CH-25-01 | 73 | 180.5 | 107.5 | 0.26 | 2.3 | 0.035 | 1.16 | 0.31 |

Including | 123.42 | 180.5 | 57.08 | 0.42 | 3.7 | 0.053 | 1.50 | 0.48 |

Including | 150.2 | 180.5 | 30.3 | 0.64 | 5.7 | 0.081 | 1.85 | 0.74 |

|

|

|

|

|

|

|

|

|

MJ-25-02 | 146 | 538 | 392 | 0.18 | 94.9 | 0.021 | 0.9 | 0.25 |

Including | 146 | 344 | 198 | 0.25 | 12.2 | 0.032 | 1.2 | 0.30 |

|

|

|

|

|

|

|

|

|

Bornite 1 | 234 | 272 | 38 | 0.49 | 30.1 | 0.075 | 2.7 | 0.59 |

Moly Core | 476 | 559 | 83 | 0.06 | 396 | 0.007 | 0.5 | 0.25 |

|

|

|

|

|

|

|

|

|

MJ-25-03 | 10 | 354 | 344 | 0.13 | 184.5 | 0.026 | 1.1 | 0.24 |

Including | 186 | 306 | 120 | 0.23 | 35.9 | 0.045 | 1.5 | 0.30 |

|

|

|

|

|

|

|

|

|

Bornite 2 | 222.8 | 235 | 12.2 | 0.43 | 91.2 | 0.095 | 2.8 | 0.57 |

Bornite 3 | 263 | 283 | 20 | 0.39 | 63.4 | 0.075 | 2.7 | 0.51 |

|

|

|

|

|

|

|

|

|

Intervals may not represent true widths which are not yet known and capping has not been applied to grades. CuEq grade calculations for reporting assumes 3-month average metal prices of US$4.3/lb Cu, US$20.6/lb Mo, US$3305/oz Au and US$33/oz Ag and recoveries of 90% Cu, 85% Mo, 70% Au, 60% Ag. Recoveries used are from recent test work on the Solaris, Warintza Project in Peru which is a similar style mineralization to Copper Road. See "Mineral Resource Estimate Update - NI 43-101 Technical Report, Warintza Project, Ecuador" with an effective date of July 1, 2024, and available on SEDAR+ under Solaris Resources profile.

Table 2. Hole locations, direction and final depths.

Hole ID | Easting | Northing | Elevation | Depth (m) | Dip | Azimuth |

CH-25-01 | 680287 | 5212436 | 507 | 375 | -70 | 0 |

MJ-25-02 | 680744 | 5212719 | 474 | 564 | -54 | 127 |

MJ-25-03 | 681125 | 5212744 | 421 | 354 | -53 | 199 |

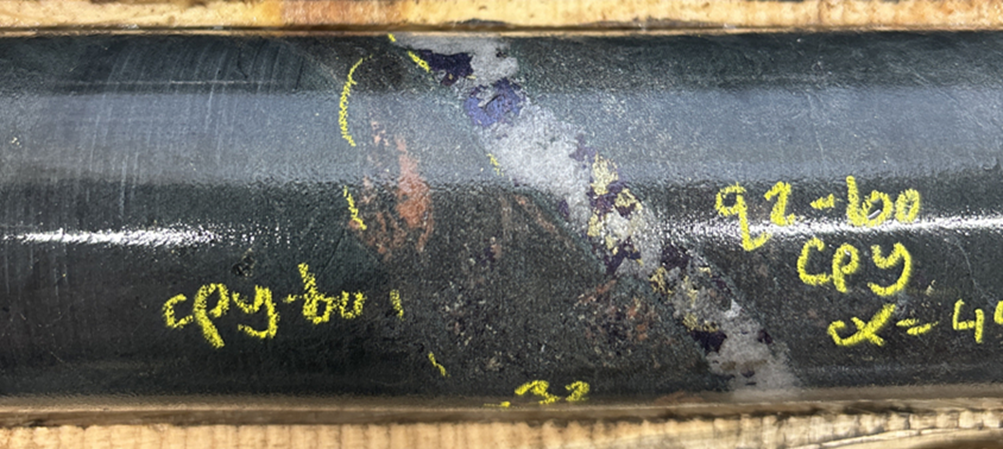

Figure 3. Massive Chalcopyrite-Magnetite mineralization at 157.7m depth grading 8.23% Cu, 1.28 g/t Au and 13.6 g/t Ag in hole CH-25-01. Host mafic volcanic is strongly biotite-altered with crosscutting quartz-orthoclase-hematite-magnetite-chalcopyrite "M"-veins.

Figure 4. Bornite-chalcopyrite in quartz A-vein hosted by biotite-chlorite altered mafic volcanic adjacent to GFP porphyry dyke in hole MJ-25-02 at 245.3m grading 0.711% Cu, 0.11 g/t Au, and 9.4 g/t Ag.

Figure 5. Intensely veined early stage "pre-mineral" GFP Porphyry dyke in hole MJ-25-02at 249.8m depth, closely associated with bornite-chalcopyrite mineralization.

Results from the initial four holes, considered with all compiled data, suggest that an extensive, and well mineralized porphyry copper system was emplaced along an extensional east-west jog formed at the confluence of two, principal regional structures. Evidence suggests that this east-west jog structure is up to 3km long by at least1 km wide and that the Company's inaugural drill program tagged only the northernmost edge and uppermost extent of this porphyry system. Future drilling by the Company will continue to test for a large, extensive porphyry copper system in the following specific ways:

At depth and along strike of the newly discovered east-west mineralized structural corridor, in particular looking for a widening of the Cu-Mo mineralization associated with this important porphyry-related structure;

To the south of the east-west mineralized structural corridor, looking for additional porphyry-related and mineralized structures and particularly ones that mark the approach of the porphyry intrusive centre;

At depth along these key structures that host the very strongly veined and mineralized porphyry dyke swarms, looking for the transition from mineralized porphyry dyke swarm into mineralized porphyry stock; and

Zones of enhanced permeability that are well mineralized; especially Cu-Mo mineralized breccia zones that may widen at depth into large, mineralized porphyry-related intrusion breccias.

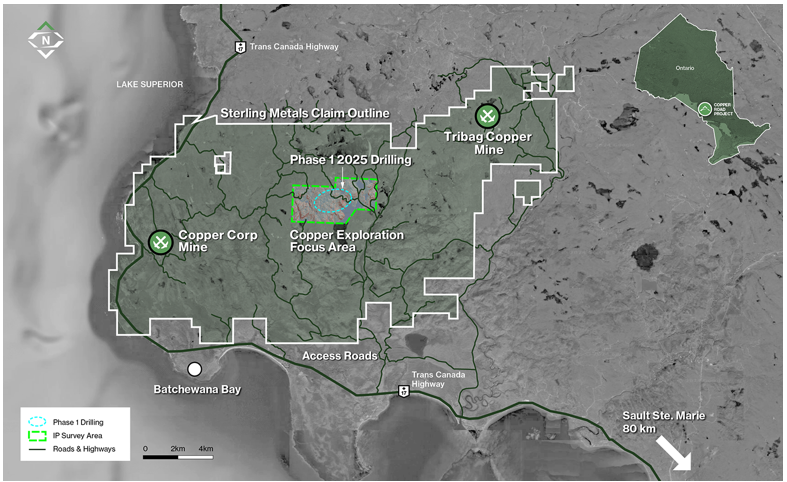

Figure 6. Location map of the Soo Copper Road Project along the Trans-Canada Highway, 80km north of Sault Ste. Marie and bridge border crossing to the U.S.

The Soo Copper Project lies at the intersection of the Midcontinent Rift and the southwestern extension of the Kapuskasking Fault Zone, a highly prospective setting historically known for smaller-scale but high-grade copper production at the former Tribag and Copper Corp mines, which anchor either end of the 30km long property. Since their respective mine closures in 1974 and 1972, fragmented ownership and consequent patchwork-type drilling efforts did not encourage the broader scale systematic exploration needed to target a large porphyry copper system1. Seeing this opportunity, one year ago Sterling acquired the Project which one year prior had for the first time seen the consolidation of a contiguous set of mineral licenses covering the most prospective geology and historical mines and prospects. The Project has since undergone comprehensive property wide data compilation, geophysical and geochemical surveys, and ground based examinations, including historical prospect and drill core re-evaluations, focused on identifying evidence for a large-scale porphyry copper system, culminating in the first drill hole of this campaign, which intersected what is believed to be one part of a high-tenor, well-preserved copper porphyry system. The recently completed maiden drill program saw a total of 1,789 metres drilled in four diamond drill holes.

1 Independent Technical Report entitled "Technical Report on the Copper Road Property", dated April 29, 2024, prepared by Kelly Malcolm, P.Geo., for Sterling Metals Corp.

Sampling Procedures - Quality Assurance/Quality Control

Analytical services were provided by Actlabs, which is an independent, CALA- and SCC-accredited analytical services firm registered to ISO 17025 and ISO 9001 standard. NQ drill core samples were logged and split in half with a diamond core saw. Half-core samples were securely stored at the core logging facility until being delivered to Actlabs North Bay lab by commercial transport. Samples were crushed (< 7 kg) up to 90% passing 2mm (10 mesh), riffle split to 250 g and pulverized by mild steel to 95% passing 105µm (150 mesh). Samples splits underwent a 4-acid near total digestion followed by a multi-element analysis, including base metals, using an ICP method for 35 elements. Selected sample pulps were then analyzed for gold using a 30 g aliquot mixed with fire assay fluxes and Ag as a collector, placed in a fire clay crucible, gradually heated to 1060ºC for 60 min, and followed with an AA finish.

Laboratory QA/QC for the ICP analysis was 14% for each batch, including 5 method reagent blanks, 10 in-house controls, 10 samples duplicates, and 8 certified reference materials. An additional 13% QA/QC was performed as part of the instrumental analysis to ensure quality in the areas of instrumental drift. Laboratory quality control for the gold fire assay included two blanks per 42 samples, three sample duplicates and 2 certified reference materials, one high and one low (QC 7 out of 42 samples). In-house QA/QC included the systematic insertion of blanks, duplicates, and certified reference materials (CRM).

Sterling Metals acknowledges that its exploration activities are conducted on the traditional lands of the First Nations and Métis Peoples of the North Shore of Lake Superior. We recognize and respect the longstanding and diverse relationships Indigenous Peoples have with the land and are committed to engaging in a manner that is respectful, transparent, and inclusive.

Qualified Person

Jeremy Niemi, P.Geo., Senior Vice President, Exploration and Evaluation for Sterling Metals has reviewed and approved the technical information presented herein.

About Sterling Metals

Sterling Metals (TSXV: SAG and OTCQB: SAGGF) is a mineral exploration company focused on large scale and high-grade Canadian exploration opportunities. The Company is advancing the 25,000-hectare Copper Road Project in Ontario which has past production, and multiple breccia and porphyry targets strategically located near robust infrastructure and the 29,000-hectare Adeline Project in Labrador which covers an entire sediment-hosted copper belt with significant silver credits. Both opportunities have demonstrated potential for important new copper discoveries, underscoring Sterling's commitment to pioneering exploration in mineral rich Canada.

For more information, please contact:

Sterling Metals Corp.

Mathew Wilson, CEO and Director

Tel: (416) 643-3887

Email: info@sterlingmetals.ca

Website: www.sterlingmetals.ca

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

This news release contains certain "forward-looking information" within the meaning of applicable securities laws. Forward looking information is frequently characterized by words such as "plan", "expect", "project", "intend", "believe", "anticipate", "estimate", "may", "will", "would", "potential", "proposed" and other similar words, or statements that certain events or conditions "may" or "will" occur. These statements are only predictions. Forward-looking information is based on the opinions and estimates of management at the date the information is provided and is subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking information. For a description of the risks and uncertainties facing the Company and its business and affairs, readers should refer to the Company's Management's Discussion and Analysis. The Company undertakes no obligation to update forward-looking information if circumstances or management's estimates or opinions should change, unless required by law. The reader is cautioned not to place undue reliance on forward-looking information.

SOURCE: Sterling Metals Corp.

View the original press release on ACCESS Newswire:

https://www.accessnewswire.com/newsroom/en/metals-and-mining/sterling-metals-intercepts-porphyry-copper-in-final-three-holes-of-the-drill-prog-1043257